Why Copper-Aluminum Fin Heat Exchangers Are Key to Refrigeration Energy Savings

Energy efficiency has become a priority in refrigeration systems. I’ve found that Copper-Aluminum Fin Heat Exchangers play a vital role in achieving this goal. These components combine copper’s excellent thermal conductivity with aluminum’s lightweight and cost-effective properties. Aluminum, in particular, stands out for its sustainability. It is highly recyclable, requiring only 5% of the energy needed to produce new aluminum. Its production also generates fewer greenhouse gas emissions compared to traditional materials. By using aluminum fins, refrigeration systems consume less energy, enhancing overall efficiency.

At senjun, we specialize in manufacturing Copper Fin Heat Exchangers and Copper-Aluminum Fin Heat Exchangers for a wide range of applications. From refrigerators and freezers to medical cooling systems, our products deliver reliable performance while supporting sustainability goals.

Key Takeaways

- Copper-Aluminum Fin Heat Exchangers save energy by using copper for heat transfer and aluminum for lightness.

- Aluminum fins make refrigeration systems lighter, using less energy and easier to set up.

- These exchangers keep cooling steady, cutting energy waste and making systems more reliable.

- Copper and aluminum can be recycled, helping the environment and supporting sustainability.

- Senjun makes these exchangers with great quality for many uses.

What Are Copper-Aluminum Fin Heat Exchangers?

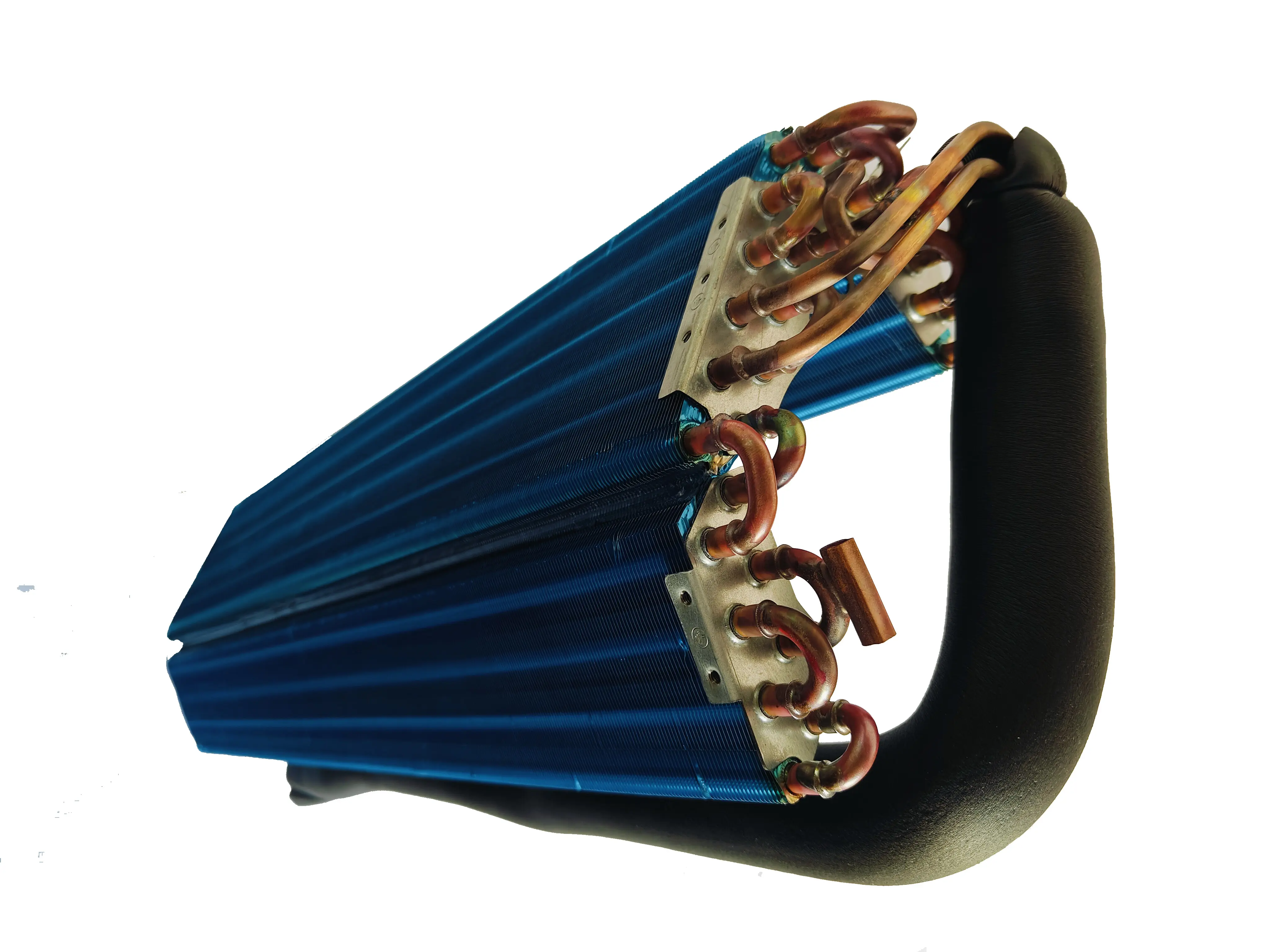

Copper-Aluminum Fin Heat Exchangers are essential components in refrigeration systems. They combine copper tubes and aluminum fins to optimize heat transfer and dissipation. Let me break down their structure, functionality, and how senjun excels in manufacturing these innovative solutions.

Structure and Components

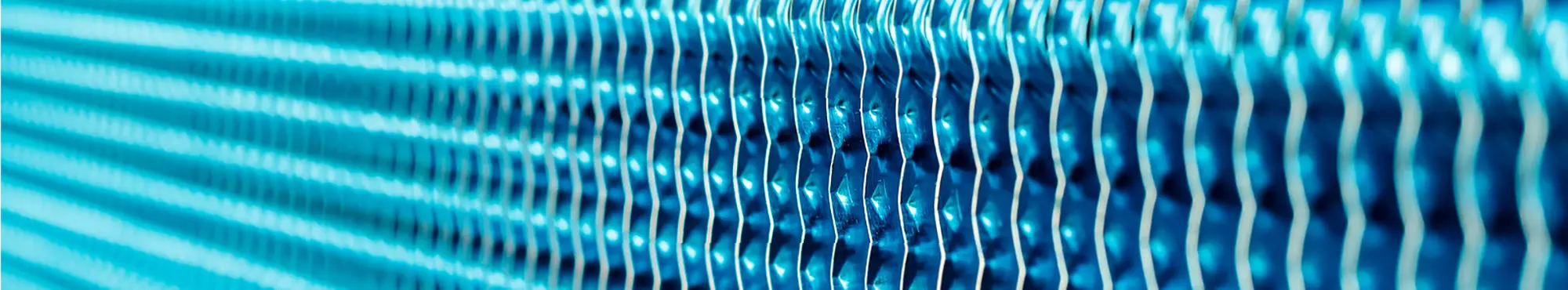

The design of Copper-Aluminum Fin Heat Exchangers is simple yet highly effective.

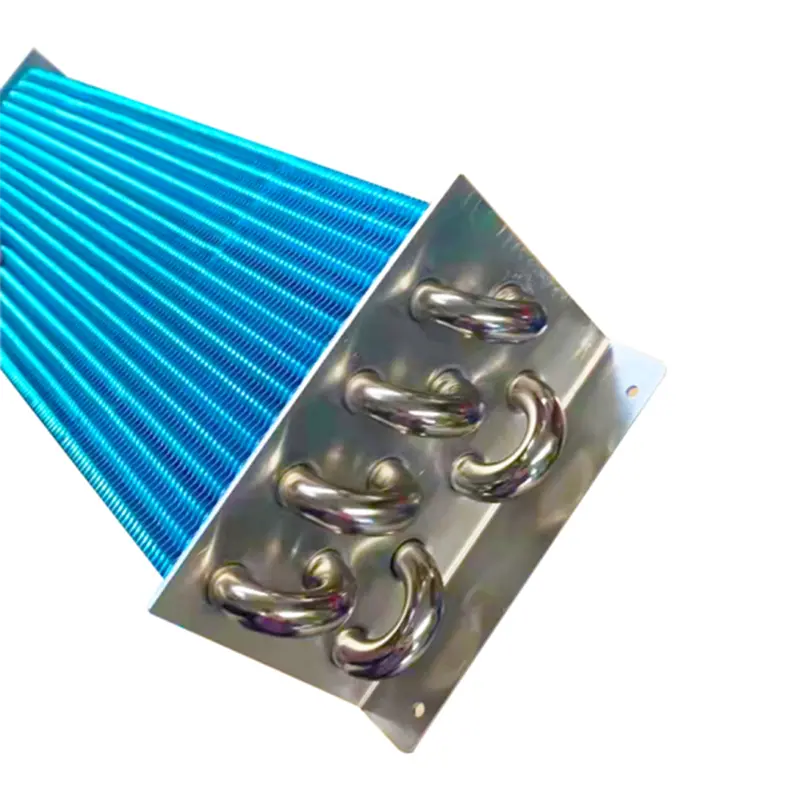

- Copper Tubes: These tubes are the backbone of the heat exchanger. Copper’s exceptional thermal conductivity ensures rapid heat transfer from the refrigerant to the tube walls. This efficiency is critical for maintaining consistent cooling performance.

- Aluminum Fins: Surrounding the copper tubes, aluminum fins provide an extended surface area for heat dissipation. While aluminum has lower thermal conductivity than copper, its lightweight nature and ability to enhance convection make it an ideal choice for fins.

This combination of materials creates a balance between performance, weight, and cost, making these heat exchangers a preferred choice in modern refrigeration systems.

How They Work in Refrigeration Systems

The operation of Copper-Aluminum Fin Heat Exchangers is straightforward yet highly efficient.

- Copper tubes conduct heat from the refrigerant to the aluminum fins.

- Aluminum fins dissipate this heat into the surrounding air, improving thermal exchange rates.

- The high thermal conductivity of copper ensures rapid heat transfer, which is vital for maintaining optimal temperatures in refrigeration cycles.

- The extended surface area of the aluminum fins enhances convection, further boosting efficiency.

This seamless integration of materials ensures that refrigeration systems operate reliably while consuming less energy.

senjun’s Role in Manufacturing

At senjun, we take pride in our expertise in producing Copper-Aluminum Fin Heat Exchangers. Our commitment to innovation and quality sets us apart in the industry. Here’s what we focus on:

- We specialize in the research, development, and production of these heat exchangers, ensuring they meet the highest standards.

- Our products undergo rigorous testing to guarantee durability and efficiency.

- We cater to a wide range of applications, including refrigerators, freezers, drinking fountains, display cabinets, wine cabinets, medical ultra-low temperature refrigerators, ice makers, and dehumidifiers.

| Product Name | Application | Materials |

|---|---|---|

| Refrigerators | Domestic cooling | Copper-aluminum fin |

| Freezers | Domestic freezing | Copper-aluminum fin |

| Drinking Fountains | Water cooling | Copper-aluminum fin |

| Display Cabinets | Product display cooling | Copper-aluminum fin |

| Wine Cabinets | Wine storage cooling | Copper-aluminum fin |

| Medical Ultra-Low Temperature Refrigerators | Medical storage | Copper-aluminum fin |

| Ice Makers | Ice production | Copper-aluminum fin |

| Dehumidifiers | Humidity control | Copper-aluminum fin |

At senjun, we combine advanced technology with a focus on sustainability. This approach allows us to deliver reliable cooling solutions that reduce energy consumption and support global sustainability goals.

How Do Copper-Aluminum Fin Heat Exchangers Enhance Energy Efficiency?

Superior Thermal Conductivity

Copper’s role in uniform temperature distribution

Copper plays a key role in the efficiency of Copper-Aluminum Fin Heat Exchangers. Its exceptional thermal conductivity, measured at 231 Btu/(hr-ft-F), ensures rapid heat transfer. This property allows the refrigerant's heat to move quickly to the copper tube walls, maintaining uniform temperature distribution. This efficiency is vital for refrigeration systems, where precise temperature control directly impacts energy consumption.

Aluminum’s contribution to faster heat dissipation

Aluminum complements copper by enhancing heat dissipation. With a thermal conductivity of 136 Btu/(hr-ft-F), aluminum fins provide an extended surface area for heat to escape into the surrounding air. This combination of materials ensures that heat is transferred and dissipated efficiently, reducing the workload on the system and saving energy.

| Metal | Thermal Conductivity (Btu/(hr-ft-F)) |

|---|---|

| Copper | 231 |

| Aluminum | 136 |

Lightweight Design

Reduced weight for lower energy consumption

The lightweight design of Copper-Aluminum Fin Heat Exchangers significantly improves energy efficiency. Aluminum fins reduce the overall weight of the system, which minimizes the strain on compressors and other components. This reduction in mechanical load translates to lower energy consumption, making these heat exchangers ideal for eco-conscious applications.

Easier installation and maintenance

I’ve noticed that the lightweight nature of aluminum also simplifies installation and maintenance. This ease of handling allows for better airflow management, which further enhances energy efficiency. As a result, systems equipped with these heat exchangers operate more effectively while requiring less effort to maintain.

The lightweight nature of aluminum fins allows for easier handling and installation, which can lead to increased energy efficiency by enabling better airflow, thus reducing the energy required for operation.

Consistent Cooling Performance

Maintaining optimal temperatures with minimal energy loss

Copper-Aluminum Fin Heat Exchangers excel at maintaining consistent cooling performance. The combination of copper’s high thermal conductivity and aluminum’s effective heat dissipation ensures rapid heat transfer. This efficiency minimizes energy loss, keeping refrigeration systems at optimal temperatures without overworking the components.

Improved system reliability and hygiene benefits

These heat exchangers also offer excellent corrosion resistance, which enhances their reliability over time. Their compact design allows them to fit into tight spaces, making them versatile for various applications. Additionally, their ability to maintain consistent cooling contributes to better hygiene in systems like medical refrigerators and food storage units, where temperature stability is critical.

- Efficient heat transfer performance ensures rapid cooling.

- Excellent corrosion resistance maintains long-term reliability.

- Compact design supports efficient cooling in limited spaces.

At senjun, we focus on creating Copper-Aluminum Fin Heat Exchangers that deliver these benefits. Our products are designed to optimize energy efficiency while meeting the diverse needs of industries ranging from residential appliances to medical cooling systems.

Advantages Over Other Materials

Comparison with All-Aluminum Systems

Enhanced durability and performance of copper-aluminum combinations

I’ve observed that Copper-Aluminum Fin Heat Exchangers outperform all-aluminum systems in durability and performance. Copper’s excellent corrosion resistance, combined with aluminum’s natural oxide layer, creates a robust and long-lasting solution. This combination reduces maintenance needs and ensures reliable operation, even in harsh environments. In contrast, all-aluminum systems, while lightweight and cost-effective, often lack the same level of durability. For refrigeration systems exposed to varying conditions, the copper-aluminum combination offers a clear advantage.

Cost-effectiveness of using aluminum fins

Aluminum fins provide a cost-effective solution without compromising efficiency. Aluminum is more affordable than copper, making it an economical choice for large-scale production. Its lightweight nature also simplifies transportation and installation, reducing associated costs. Over time, these savings add up, making Copper-Aluminum Fin Heat Exchangers a budget-friendly option for businesses and consumers alike.

Comparison with All-Copper Systems

Lightweight advantage of aluminum fins

The inclusion of aluminum fins significantly reduces the weight of Copper-Aluminum Fin Heat Exchangers compared to all-copper systems. This lightweight design minimizes the strain on refrigeration components, leading to lower energy consumption. I’ve found that this feature not only enhances energy efficiency but also makes installation and maintenance much easier.

Reduced material costs without compromising efficiency

Copper is one of the most expensive materials used in heat exchangers. By incorporating aluminum fins, manufacturers like senjun can reduce material costs while maintaining high thermal efficiency. Aluminum fins enhance heat dissipation and improve overall system performance, proving that cost savings don’t have to come at the expense of quality.

Overall Benefits

Balance of performance, cost, and durability

Copper-Aluminum Fin Heat Exchangers strike the perfect balance between performance, cost, and durability. Copper ensures efficient heat transfer, while aluminum maximizes the heat exchange surface area. Together, they create a system that is both reliable and cost-effective.

Versatility in various refrigeration applications

These heat exchangers are versatile and suitable for a wide range of applications. From residential refrigerators to industrial cooling systems, they deliver consistent performance. At senjun, we specialize in creating solutions tailored to diverse needs, ensuring that our products meet the highest standards of efficiency and reliability.

The combination of copper and aluminum offers unmatched benefits, making Copper-Aluminum Fin Heat Exchangers a preferred choice for modern refrigeration systems.

Environmental and Economic Impact

Energy Savings and Carbon Emissions

Reduced energy consumption leading to lower emissions

Copper-Aluminum Fin Heat Exchangers significantly reduce energy consumption in refrigeration systems. I’ve seen how businesses benefit from these savings. For example:

- 3M Korea saved approximately $320,000 in 2023 and is projected to save $440,000 in 2024.

- The implementation of these heat exchangers reduced carbon output by over 1,100 metric tons.

This reduction in energy use directly lowers greenhouse gas emissions. By consuming less electricity, these systems contribute to a cleaner environment. The combination of copper tubing and aluminum fins creates an efficient heat transfer system. This design enhances durability and reduces the carbon footprint of refrigeration systems. It also helps industries meet stricter regulations for greener products.

Contribution to global sustainability goals

Copper-Aluminum Fin Heat Exchangers align with global sustainability goals. Aluminum’s recyclability and lower greenhouse gas emissions during production make it an eco-friendly choice. These heat exchangers also reduce energy usage in applications, supporting industries in their efforts to adopt sustainable practices.

Long-Term Cost Savings

Lower operational costs for businesses and consumers

I’ve noticed that these heat exchangers lower operational costs for both businesses and consumers. Their energy-efficient design reduces electricity bills, making them a cost-effective solution. Over time, the savings add up, especially for large-scale refrigeration systems.

Reduced maintenance and replacement expenses

The durability of Copper-Aluminum Fin Heat Exchangers minimizes maintenance needs. Copper’s corrosion resistance and aluminum’s lightweight properties ensure long-lasting performance. This reliability reduces the frequency of replacements, saving money and resources in the long run.

Recycling and Material Reuse

Recyclability of copper and aluminum components

Copper and aluminum are highly recyclable materials. Copper can be recycled indefinitely without losing its quality. This process keeps valuable resources in use and reduces waste. Aluminum recycling requires only 5% of the energy needed to produce new aluminum, further conserving resources.

Supporting circular economy practices

Recycling these metals supports circular economy practices. By reusing materials, we conserve natural resources and minimize environmental impacts. At senjun, we prioritize sustainability by designing products that align with these principles. Our Copper-Aluminum Fin Heat Exchangers not only enhance energy efficiency but also contribute to a more sustainable future.

Applications in Modern Refrigeration

Copper-Aluminum Fin Heat Exchangers play a crucial role in various refrigeration applications. Their versatility and efficiency make them indispensable in industrial, residential, and emerging technologies.

Industrial and Commercial Refrigeration

Use in cold storage facilities and food processing

I’ve seen how Copper-Aluminum Fin Heat Exchangers enhance refrigeration in industrial settings. They are widely used in cold storage facilities to maintain low temperatures for perishable goods. In food processing plants, these heat exchangers ensure precise temperature control, which is essential for preserving food quality and safety. Their ability to handle large-scale cooling needs makes them a reliable choice for industrial refrigeration.

Role in large-scale HVAC systems

In commercial HVAC systems, these heat exchangers optimize heat transfer and improve energy efficiency. They are commonly found in air conditioning units, vehicular coolers, and even heat sinks for electronic equipment. Their lightweight design reduces the strain on system components, leading to lower energy consumption and operational costs. This makes them a preferred option for businesses aiming to reduce their carbon footprint.

Residential and Consumer Appliances

Application in refrigerators, freezers, and air conditioners

In residential appliances, Copper-Aluminum Fin Heat Exchangers ensure effective heat transfer and long-lasting performance. I’ve noticed that their corrosion resistance reduces the need for frequent replacements, saving energy and costs over time. Their lightweight nature allows for flexible designs, making them suitable for refrigerators, freezers, and air conditioners. These features contribute to the growing demand for energy-efficient home appliances.

Contribution to energy-efficient home appliances

The combination of copper’s thermal conductivity and aluminum’s lightweight properties enhances the performance of residential cooling systems. This synergy not only improves energy efficiency but also simplifies installation and maintenance. By reducing energy consumption, these heat exchangers help homeowners lower their electricity bills while supporting sustainable living.

Emerging Technologies

Integration in smart and eco-friendly refrigeration systems

I’ve observed a growing trend of integrating Copper-Aluminum Fin Heat Exchangers into smart refrigeration systems. These systems often use natural refrigerants like carbon dioxide (CO2) and propane (R290), which are more eco-friendly. The heat exchangers’ efficient heat transfer and compact design make them ideal for these applications, ensuring optimal performance while minimizing environmental impact.

Potential for innovation in renewable energy-powered cooling

The demand for renewable energy-powered cooling solutions is rising. Copper-Aluminum Fin Heat Exchangers are well-suited for these innovations due to their durability and efficiency. Their ability to work seamlessly with natural refrigerants reflects a shift toward greener technologies. I believe this trend will continue to grow, driving advancements in sustainable refrigeration.

At senjun, we specialize in manufacturing Copper-Aluminum Fin Heat Exchangers for a wide range of applications. From industrial facilities to residential appliances, our products deliver reliable performance while supporting energy efficiency and sustainability.

Copper-Aluminum Fin Heat Exchangers have become essential for energy-efficient refrigeration. Their combination of copper’s thermal conductivity and aluminum’s lightweight design optimizes energy use while supporting sustainability goals. Small-diameter copper tubes and aluminum fins enhance efficiency, reduce refrigerant use, and align with environmental standards. At senjun, we focus on innovation and quality. By combining advanced technology with customer insights, we deliver reliable, energy-saving solutions. Our rigorous testing ensures durable products that meet diverse needs. These heat exchangers represent a cornerstone of sustainable refrigeration, driving progress in both environmental and economic performance.

FAQ

What makes Copper-Aluminum Fin Heat Exchangers energy-efficient?

Copper’s high thermal conductivity ensures rapid heat transfer, while aluminum fins enhance heat dissipation. This combination reduces energy consumption by optimizing cooling performance. At senjun, we design these heat exchangers to maximize efficiency, helping refrigeration systems operate with minimal energy loss.

Why are Copper-Aluminum Fin Heat Exchangers better than all-copper systems?

Copper-Aluminum Fin Heat Exchangers weigh less due to aluminum fins, reducing strain on refrigeration components. Aluminum also lowers material costs without sacrificing efficiency. I’ve found this combination delivers excellent performance while being more affordable and easier to handle than all-copper systems.

How does senjun ensure the quality of its heat exchangers?

At senjun, we conduct rigorous testing on every product to ensure durability and efficiency. Our team focuses on research and development to create innovative solutions. We specialize in producing heat exchangers for various applications, including refrigerators, freezers, and medical cooling systems.

Are Copper-Aluminum Fin Heat Exchangers environmentally friendly?

Yes, they are. Copper and aluminum are recyclable materials. Aluminum recycling uses only 5% of the energy required for new production. By reducing energy consumption and supporting recycling, these heat exchangers contribute to sustainability goals. At senjun, we prioritize eco-friendly practices in our manufacturing process.

What industries benefit from senjun’s Copper-Aluminum Fin Heat Exchangers?

Our heat exchangers serve industries like residential appliances, medical refrigeration, and commercial HVAC systems. They’re used in refrigerators, freezers, wine cabinets, and dehumidifiers. At senjun, we tailor our products to meet the diverse needs of these industries, ensuring reliable and efficient cooling solutions.