Noisy Refrigeration System? 4 Parts That Might Be the Culprit

A noisy refrigerator can be more than just an annoyance; it often signals mechanical problems. Common culprits include:

- Dirty condenser coils

- Improper leveling

- Worn-out door gaskets

- Faulty fan motors

- Compressor problems

These issues can escalate if ignored. For example, a malfunctioning fan motor might affect the copper fin heat exchanger, reducing efficiency. Addressing noise early prevents costly repairs and extends your appliance's life.

Key Takeaways

- Find usual noise makers in your fridge, like the compressor, fans, defrost timer, and heat exchanger.

- Clean and tighten parts often to stop noise and help your fridge last longer.

- Call an expert for hard problems to avoid more damage and fix it safely.

Compressor

What Does the Compressor Do?

The compressor serves as the heart of your refrigeration system. It pressurizes refrigerant gas, enabling it to circulate through the system and absorb heat efficiently. Without this critical component, the cooling process would fail.

Compressors are essential in refrigeration and other industries. They increase gas pressure for purposes like refrigeration, pneumatic transportation, and power production. Their efficiency and reliability directly impact energy consumption and operational performance.

Common Noises from a Faulty Compressor

A malfunctioning compressor often produces distinct sounds. These noises can include:

- Humming or buzzing: Indicates electrical issues or internal mechanical wear.

- Clicking: Suggests the compressor is struggling to start.

- Knocking or rattling: Points to loose internal components or mounting issues.

Interestingly, compressors are known for their noise levels. For instance, portable air compressors average 88 dBA at a distance of 7 meters. Proper maintenance can significantly reduce noise emissions, improving overall system performance.

How to Address Compressor Issues

Addressing compressor noise requires a systematic approach. First, inspect the compressor for visible damage or loose parts. Tighten any loose bolts or screws. If the noise persists, check the electrical connections and ensure they are secure. Cleaning the surrounding area can also help reduce vibrations.

For persistent or severe issues, I recommend consulting a professional technician. Compressors operate under high pressure, and improper handling can lead to further damage or safety risks. Always prioritize safety and efficiency when dealing with this vital component.

Condenser Fan

What Is the Role of the Condenser Fan?

The condenser fan plays a critical role in maintaining your refrigeration system's efficiency. It helps dissipate heat by drawing air over the condenser coils, ensuring the refrigerant cools effectively. Without proper airflow, the system would overheat, leading to reduced cooling performance and potential damage to other components.

Noises Indicating a Problem with the Condenser Fan

A noisy condenser fan often signals underlying issues. I’ve observed that these fans can produce significant noise levels, with sound pressure reaching an average of 88.6 dB(A) at a distance of five feet. This noise primarily stems from aerodynamic factors, especially in the 100 Hz octave band. Additionally, the hydraulic motor contributes to the overall sound pressure level of 88.5 dB(A). These measurements highlight the fan's substantial impact on system noise.

To better understand the noise behavior, here’s a summary of a technical noise measurement study:

| Measurement Aspect | Details |

|---|---|

| Measurement Environment | Quiet room |

| Microphone Type | ½ inch condenser microphone |

| Measurement Height | 30 mm above the rotation axis center from the fan suction side |

| Recording Duration | 10 seconds |

| Sampling Frequency | 51.2 kHz |

| Sample Size | 512,000 samples (10 seconds) |

| Short Time Analysis Sample Size | 5,120 samples (0.1 seconds) |

| Purpose of Measurement | To capture behavior change for accurate analysis |

Fixes for a Noisy Condenser Fan

Addressing condenser fan noise requires a methodical approach. I recommend starting with a thorough inspection of the fan assembly. Look for cracks or damage and listen for vibrations during operation. Overheating in bearings or motors often causes noise, so use an infrared camera to check for temperature anomalies. Ensure all safety devices, like vibration switches, function properly to prevent further damage.

Conventional silencers or barriers may not effectively reduce low-frequency noise. Instead, aerodynamic techniques can significantly lower noise levels while improving fan efficiency. These methods address the root cause of the noise, ensuring a quieter and more efficient refrigeration system.

Evaporator Fan

What Does the Evaporator Fan Do?

The evaporator fan plays a vital role in your refrigeration system. It circulates cold air from the evaporator coils throughout the refrigerator and freezer compartments. This ensures consistent cooling and prevents uneven temperatures. Without this fan, cold air would remain stagnant, leading to spoiled food and reduced efficiency. I often describe it as the component that keeps your refrigerator’s airflow in check.

Signs of a Malfunctioning Evaporator Fan

A faulty evaporator fan often reveals itself through unusual sounds or performance issues. Here are some common signs I’ve encountered:

- Loud squealing or grinding noises: These often indicate worn-out bearings.

- Inconsistent cooling: Warm spots in the refrigerator suggest the fan isn’t circulating air properly.

- Complete silence: If the fan stops running entirely, it may have failed.

Pay attention to these symptoms. They can help you identify the problem early and prevent further damage.

Steps to Resolve Evaporator Fan Noise

Resolving evaporator fan noise requires a systematic approach. I recommend the following steps:

- Inspect the fan motor for loose components, debris, or worn bearings.

- Check electrical connections for damaged or loose wiring.

- Test the capacitor with a multimeter and replace it if necessary.

- Examine motor windings for signs of overheating or wear.

- Regularly clean and lubricate the motor to prevent overheating.

Tip: Always disconnect the refrigerator from power before performing any maintenance. If the issue persists, consult a professional to avoid further complications.

Defrost Timer

What Is the Function of the Defrost Timer?

The defrost timer ensures your refrigeration system operates efficiently by preventing ice buildup on the evaporator coils. It automatically initiates defrost cycles at regular intervals, melting accumulated frost and maintaining optimal cooling performance. Modern defrost timers have advanced features that enhance energy efficiency and system reliability.

- The defrost cycle starts automatically and completes efficiently.

- The system monitors parameters to trigger new cycles as needed.

- The timer works with other methods to control cycle frequency.

Some systems, like those developed by Danfoss, integrate defrost management with other refrigeration operations. These electronic controls replace traditional mechanical timers, offering greater flexibility and precision.

Sounds Associated with a Faulty Defrost Timer

A malfunctioning defrost timer often produces unusual noises. I’ve noticed that clicking or ticking sounds are common indicators. These noises occur when the timer struggles to switch between cooling and defrost modes. In some cases, the timer may emit a continuous hum, signaling internal wear or electrical issues. Ignoring these sounds can lead to ice buildup, reduced cooling efficiency, and potential damage to other components.

Solutions for Defrost Timer Issues

Addressing defrost timer problems requires a systematic approach. First, understand how the timer operates under normal conditions. If the freezer isn’t defrosting regularly, inspect the timer for visible damage or incorrect settings.

- Check if the timer is functioning properly.

- Replace it if it’s faulty to restore normal operation.

- Ensure the replacement part matches your freezer model.

I recommend consulting your freezer’s manual to locate the timer and verify its functionality. If you’re unsure, seek professional assistance to avoid further complications. A well-maintained defrost timer ensures your refrigeration system runs smoothly and efficiently.

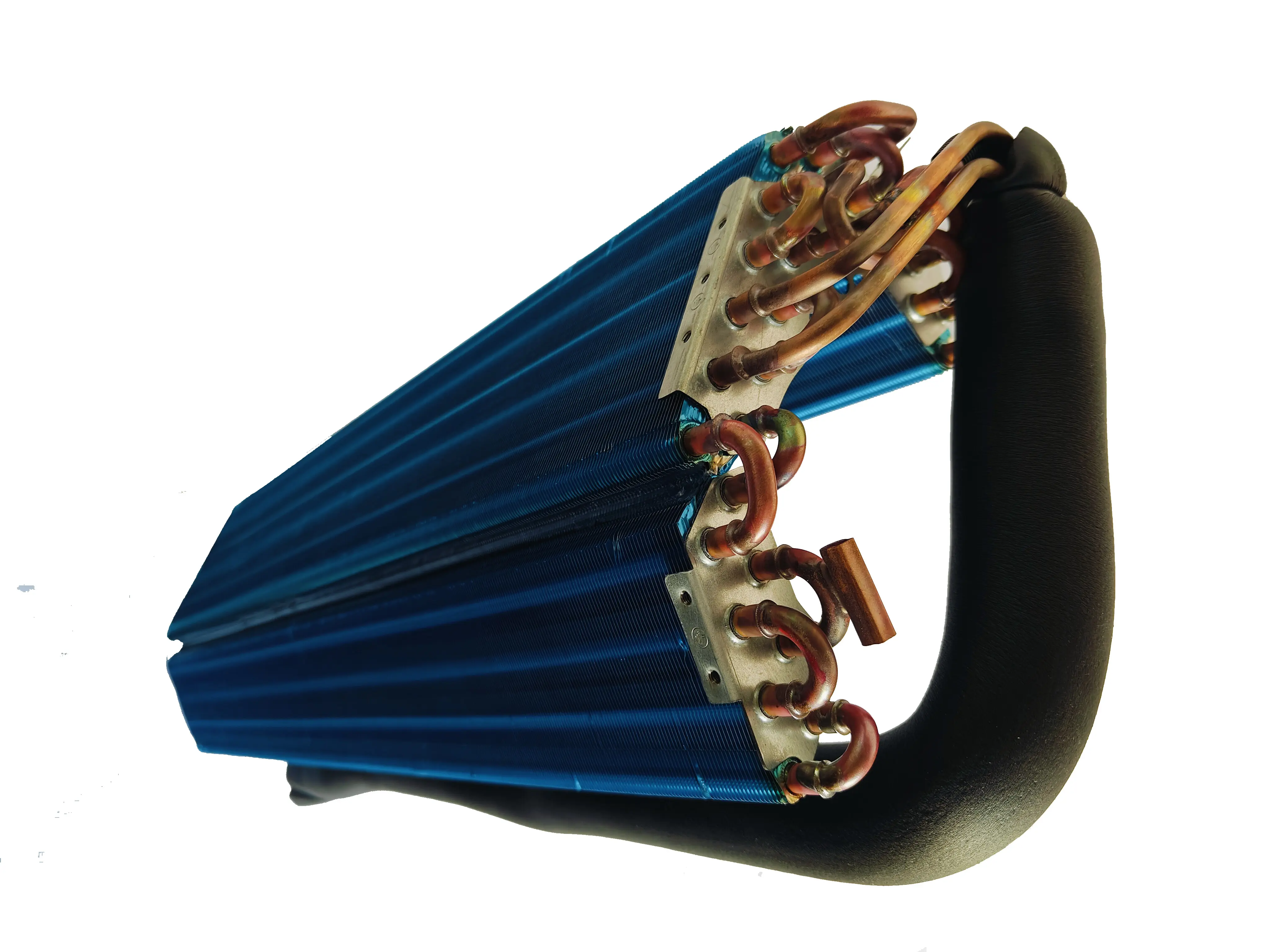

Copper Fin Heat Exchanger

What Is a Copper Fin Heat Exchanger?

The copper fin heat exchanger is a vital component in refrigeration systems. It facilitates efficient heat transfer by allowing refrigerant to release heat into the surrounding air. Copper fins are widely used due to their exceptional thermal conductivity and durability. I’ve observed that copper outperforms materials like aluminum and stainless steel in heat exchange efficiency. Research confirms that copper fins achieve a higher air-side heat transfer coefficient, making them ideal for refrigeration systems requiring consistent cooling performance.

How It Contributes to Noise in Refrigeration Systems

Copper fin heat exchangers can contribute to noise when airflow encounters obstructions or when the fins accumulate dirt and debris. Vibrations from nearby components, such as fans or compressors, may amplify the noise. I’ve noticed that irregular airflow patterns around the fins often result in whistling or humming sounds. These issues not only disrupt the system’s quiet operation but also reduce its overall efficiency. Proper maintenance minimizes these noise-related problems and ensures optimal performance.

Tips for Maintaining a Copper Fin Heat Exchanger

Maintaining the copper fin heat exchanger is essential for reducing noise and improving efficiency. I recommend cleaning the fins regularly to remove dust and debris that obstruct airflow. Use a soft brush or compressed air to avoid damaging the fins. Inspect the surrounding components for vibrations that might affect the heat exchanger. Tighten loose screws or bolts to stabilize the system. If corrosion appears on the fins, apply a protective coating to extend their lifespan. Routine maintenance ensures the copper fin heat exchanger operates quietly and efficiently.

Identifying the source of refrigerator noise is crucial for maintaining efficiency and preventing costly repairs. The five common culprits include the compressor, condenser fan, evaporator fan, defrost timer, and copper fin heat exchanger. Each part contributes differently to overall noise levels, as shown below:

| Component | Noise Contribution (%) | Common Issues |

|---|---|---|

| Motors (Compressor, Fans) | 60% | Wear, loose parts |

| Airflow (Heat Exchangers) | 30% | Obstructions, debris buildup |

| Other Mechanical Parts | 10% | Vibrations, misalignment |

Simple fixes like cleaning or tightening parts often resolve minor issues. For complex problems, I recommend consulting a professional. Companies like senjun specialize in high-quality refrigeration components, including copper fin heat exchangers, ensuring quieter and more efficient systems.

FAQ

What should I do if my refrigerator makes a loud humming noise?

Inspect the compressor and fans for loose parts or debris. Clean the components and tighten screws. If the noise persists, consult a professional technician.

How often should I clean the copper fin heat exchanger?

I recommend cleaning it every three to six months. Use a soft brush or compressed air to remove dust and debris without damaging the fins.

Can I fix a noisy evaporator fan myself?

Yes, you can inspect for loose components, debris, or worn bearings. Disconnect the power before maintenance. For complex issues, I suggest contacting a professional.