4 International Safety Standards for Medical-Grade Heat Exchangers

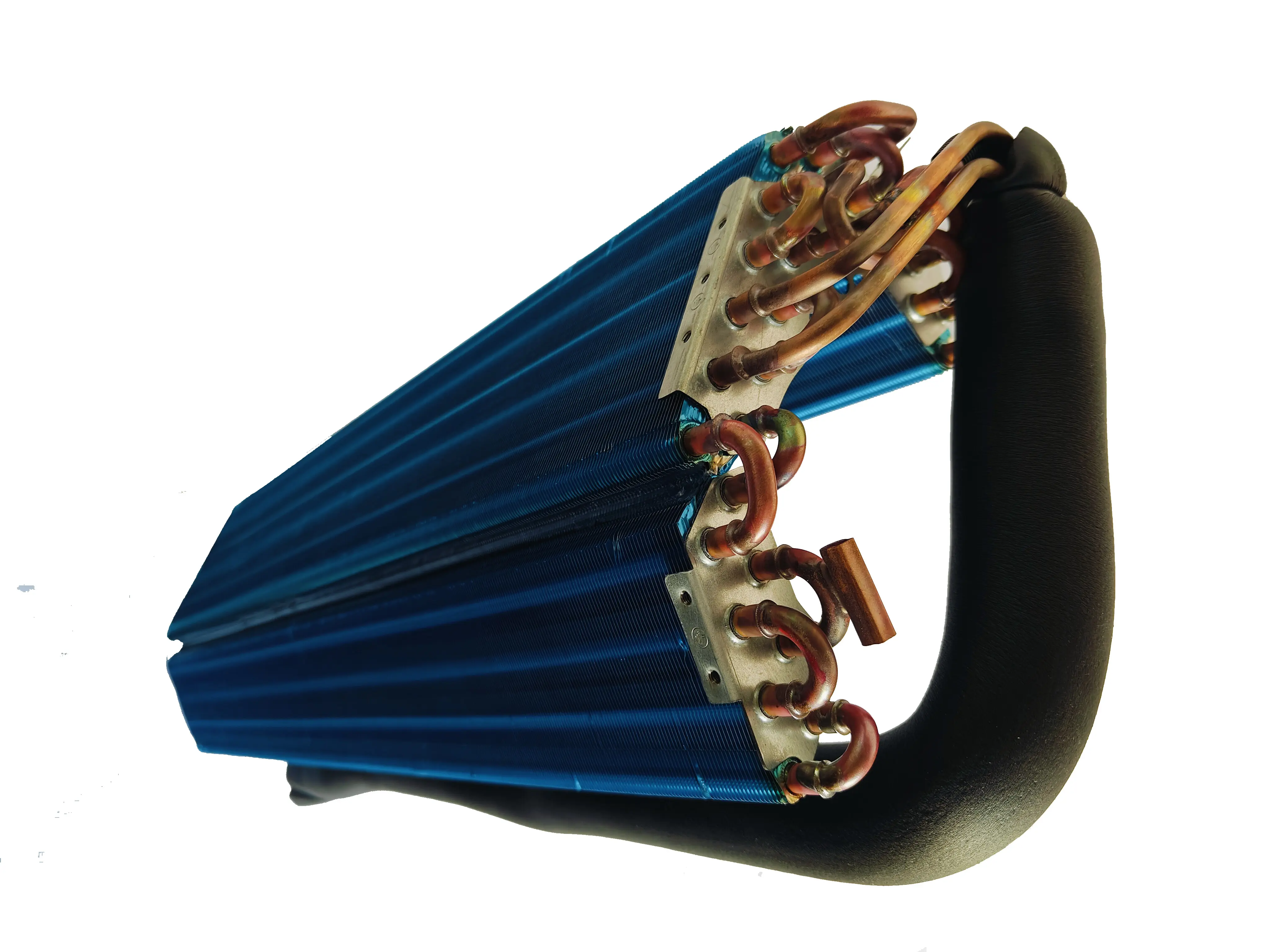

International safety standards play a critical role in ensuring the reliability of medical-grade heat exchangers. These standards safeguard patient health by minimizing risks and enhancing operational efficiency in medical environments. Manufacturers must adhere to these guidelines to maintain consistent product quality and meet regulatory expectations. For instance, Ningbo Senjun New Materials Co., Ltd. specializes in producing advanced solutions like the copper fin heat exchanger, which complies with stringent safety requirements. Their expertise ensures that medical devices operate safely and efficiently, contributing to better healthcare outcomes.

Key Takeaways

- ISO 13485 checks quality in medical devices. It helps makers follow safety rules.

- ISO 14971 focuses on risk control. It helps find and fix dangers in medical heat exchangers.

- IEC 60601-1 ensures electrical safety. It makes sure heat exchangers work safely with power systems.

- ASME BPE supports clean designs. It helps stop contamination in medical spaces.

- Regular checks and knowing new rules are key. They help makers stay safe and improve products.

ISO 13485: Quality Management Systems for Medical Devices

Overview of ISO 13485

Purpose and scope of the standard.

ISO 13485 serves as the global benchmark for quality management systems in the medical device industry. It focuses on ensuring that products consistently meet customer and regulatory requirements. This standard applies to every stage of a product's lifecycle, from design and development to production and servicing. By adopting ISO 13485, manufacturers can demonstrate their commitment to quality and safety, which is critical in the healthcare sector.

Applicability to medical-grade heat exchangers.

Medical-grade heat exchangers, such as the copper fin heat exchanger, play a vital role in maintaining precise temperature control in medical devices. Compliance with ISO 13485 ensures that these components meet stringent quality standards, reducing the risk of failure in critical applications. This standard also facilitates seamless integration with other medical equipment, enhancing overall system reliability.

Key Compliance Requirements

Documentation and process control.

ISO 13485 emphasizes robust documentation and process control. Manufacturers must maintain detailed records of their production processes, ensuring traceability and consistency. This requirement not only supports regulatory compliance but also streamlines internal operations. For example, companies like Ningbo Senjun New Materials Co., Ltd. leverage these practices to produce high-quality copper fin heat exchangers that meet global standards.

Risk management and product traceability.

Risk management is another cornerstone of ISO 13485. The standard requires manufacturers to identify potential risks, implement control measures, and monitor their effectiveness. Additionally, product traceability ensures that any issues can be quickly identified and resolved. These practices are essential for maintaining the safety and reliability of medical-grade heat exchangers.

Relevance to Medical-Grade Heat Exchangers

Ensuring consistent quality in manufacturing.

Adhering to ISO 13485 helps manufacturers maintain consistent quality in their production processes. This consistency is crucial for medical-grade heat exchangers, which must perform reliably under demanding conditions. Many large medical device companies prefer working with ISO 13485-certified vendors, highlighting the market's trust in this standard.

Examples of compliance in heat exchanger production.

Compliance with ISO 13485 has tangible benefits. For instance, companies that adopt this standard often experience financial gains and improved product quality. The documentation requirements also facilitate better collaboration among development teams, reducing time and costs. At Ningbo Senjun New Materials Co., Ltd., these principles guide the production of copper fin heat exchangers, ensuring they meet the highest quality standards.

ISO 14971: Risk Management for Medical Devices

Overview of ISO 14971

Focus on identifying and mitigating risks.

ISO 14971 serves as the global standard for risk management in medical device development. It emphasizes identifying, assessing, and mitigating risks throughout the product lifecycle. This approach ensures that medical devices, including heat exchangers, meet safety and performance expectations. By integrating risk management into every stage, manufacturers can proactively address potential hazards, reducing the likelihood of adverse events.

Applicability to medical-grade heat exchangers.

Medical-grade heat exchangers, such as the Copper Fin Heat Exchanger, are critical components in healthcare equipment. These devices must operate reliably under stringent conditions. ISO 14971 ensures that manufacturers address risks like contamination, system failures, and thermal inefficiencies. This standard is particularly relevant for heat exchangers used in sensitive applications, such as medical refrigeration or ultra-low temperature systems.

Key Compliance Requirements

Risk analysis and evaluation processes.

ISO 14971 outlines a structured process for risk analysis and evaluation. Manufacturers must identify potential hazards, assess their severity and likelihood, and determine acceptable risk levels. Key components include:

- Risk Management Planning: Developing a strategy to manage risks.

- Risk Analysis: Identifying hazards and their impacts.

- Risk Evaluation: Assessing the probability and severity of risks.

This systematic approach ensures that risks are thoroughly understood and managed effectively.

Implementation of risk control measures.

Once risks are identified, ISO 14971 requires implementing control measures to mitigate them. These measures may include design modifications, material changes, or enhanced testing protocols. For example, manufacturers might use biocompatible materials or advanced sterilization techniques to prevent contamination. Post-market surveillance further ensures that any residual risks are monitored and addressed.

Relevance to Medical-Grade Heat Exchangers

Preventing contamination and system failures.

ISO 14971 plays a vital role in preventing contamination and system failures in medical-grade heat exchangers. By adhering to this standard, manufacturers can ensure that their products meet the highest safety and reliability standards. For instance, risk controls like sterilization validation and continuous monitoring help maintain product integrity in demanding medical environments.

Case studies of risk management in heat exchanger design.

Practical applications of ISO 14971 demonstrate its effectiveness. Manufacturers often implement risk controls, such as enhanced cleaning protocols, to reduce contamination risks. They also monitor post-production performance to identify and address unforeseen issues. These practices ensure that medical-grade heat exchangers, including the Copper Fin Heat Exchanger, deliver consistent performance and safety.

IEC 60601-1: Safety Standards for Medical Electrical Equipment

Overview of IEC 60601-1

Emphasis on electrical safety and performance.

IEC 60601-1 is the cornerstone standard for ensuring the safety and performance of medical electrical equipment. It focuses on protecting patients and operators from electrical hazards. This includes stringent requirements for insulation, grounding, and leakage current limits. By adhering to these guidelines, manufacturers can ensure their devices meet global safety expectations.

Applicability to medical-grade heat exchangers.

Medical-grade heat exchangers, especially those integrated into electrical systems, must comply with IEC 60601-1. For example, a Copper Fin Heat Exchanger used in medical refrigeration systems must meet insulation and leakage current standards to prevent electrical faults. This ensures the device operates safely in critical healthcare environments.

Key Compliance Requirements

Electrical insulation and grounding.

IEC 60601-1 mandates robust insulation and grounding to prevent electric shock. Devices are classified based on their insulation and grounding requirements, as shown below:

| Class/Type | Description |

|---|---|

| Class I | Live part covered by basic insulation and protective earth |

| Class II | Live part covered by double or reinforced insulation |

| Class IP | Internal power supply |

| Type B | Patient applied part earthed |

| Type BF | Patient applied part floating (surface conductor) |

| Type CF | Patient applied part floating for use in direct contact with the heart |

These classifications ensure that medical devices, including heat exchangers, meet the necessary safety levels for their intended applications.

Testing and certification processes.

Compliance with IEC 60601-1 requires rigorous testing. This includes dielectric strength testing at 110% of mains voltage, leakage current measurements under normal and single-fault conditions, and protective earth resistance checks. These tests validate the device's ability to operate safely under various conditions, ensuring reliability in medical settings.

Relevance to Medical-Grade Heat Exchangers

Ensuring safe integration with medical devices.

Medical-grade heat exchangers must integrate seamlessly with other medical devices while maintaining electrical safety. For instance, a Copper Fin Heat Exchanger used in ultra-low temperature systems must comply with IEC 60601-1 to ensure it does not compromise the safety of the overall system. This standard guarantees that the heat exchanger operates reliably without posing risks to patients or operators.

Examples of compliance in electrical heat exchangers.

Manufacturers often implement advanced design features to meet IEC 60601-1 requirements. For example, they may use reinforced insulation and floating patient-applied parts to minimize leakage currents. The table below highlights the specific leakage current limits for different device types:

| Classification | Input-to-Output Isolation | Input-to-Ground Isolation | Output-to-Ground Isolation | Maximum Leakage Current (Normal) | Maximum Leakage Current (Single Fault) |

|---|---|---|---|---|---|

| Type B | 4,000 VAC | 1,500 VAC | 500 VAC | 100 µA | 500 µA |

| Type BF | 4,000 VAC | 1,500 VAC | 1,500 VAC | 100 µA | 500 µA |

| Type CF | 4,000 VAC | 1,500 VAC | 1,500 VAC | 10 µA | 50 µA |

These measures ensure that medical-grade heat exchangers meet the highest safety standards, providing peace of mind to healthcare providers and patients alike.

ASME BPE: Bioprocessing Equipment Standards

Overview of ASME BPE

Focus on hygienic design and materials.

The ASME BPE (Bioprocessing Equipment) standards emphasize hygienic design and material selection, which are critical for medical-grade heat exchangers. These standards address every aspect of equipment design, including system layout, material compatibility, and fabrication techniques. By adhering to ASME BPE, manufacturers ensure that their products meet the stringent cleanliness and safety requirements of the medical and pharmaceutical industries. This focus on hygiene minimizes contamination risks, making these standards indispensable for medical applications.

Applicability to medical-grade heat exchangers.

Medical-grade heat exchangers, such as the Copper Fin Heat Exchanger, must comply with ASME BPE to maintain sterility and operational efficiency. These standards ensure that the materials and designs used in heat exchangers are suitable for bioprocessing environments. For instance, ASME BPE compliance guarantees that the equipment can withstand rigorous cleaning and sterilization processes without compromising performance or safety.

Key Compliance Requirements

Use of biocompatible materials.

ASME BPE mandates the use of biocompatible materials to ensure safety in medical applications. These materials must resist corrosion, maintain structural integrity, and avoid adverse reactions with biological substances. The standards also enhance customer confidence by certifying that the equipment meets federal regulations. For medical-grade heat exchangers, this means using materials that support both durability and biocompatibility, ensuring long-term reliability in sensitive environments.

Cleanability and sterilization standards.

Cleanability and sterilization are central to ASME BPE compliance. The standards require equipment to undergo advanced testing and certification to verify its ability to meet stringent hygiene requirements. For example, manufacturers must design heat exchangers with smooth surfaces and minimal crevices to facilitate thorough cleaning. This ensures that the equipment remains free from contaminants, even after repeated use in demanding medical settings.

Relevance to Medical-Grade Heat Exchangers

Preventing contamination in medical environments.

ASME BPE plays a vital role in preventing contamination in medical-grade heat exchangers. By adhering to these standards, manufacturers can produce equipment that meets the highest hygiene and safety benchmarks. This is particularly important in medical environments, where even minor contamination can have severe consequences. For instance, the Copper Fin Heat Exchanger benefits from ASME BPE compliance by maintaining sterility and ensuring consistent performance.

Examples of compliance in bioprocessing heat exchangers.

Manufacturers often implement ASME BPE standards to enhance the quality and reliability of their heat exchangers. For example, they may use biocompatible materials and advanced cleaning protocols to meet regulatory requirements. These practices not only improve product quality but also streamline compliance with federal current Good Manufacturing Practices (cGMP). By following ASME BPE guidelines, companies like Ningbo Senjun New Materials Co., Ltd. ensure that their heat exchangers deliver exceptional performance in medical and bioprocessing applications.

Adhering to international safety standards is essential for ensuring the safety, reliability, and compliance of medical-grade heat exchangers. These standards, such as ISO 13485 and ASME BPE, provide a framework that minimizes risks and enhances product quality. For instance, the TEMA standards ensure the performance of shell and tube heat exchangers by addressing critical aspects like design and material properties.

| Standard | Description |

|---|---|

| TEMA | Provides widely recognized standards for shell and tube heat exchangers, categorized into classes for different applications. |

| ASME | Sets crucial standards for pressurized components, ensuring safety and performance. |

| ANSI | Coordinates U.S. voluntary standardization, ensuring standards evolve with industry needs. |

| PED | Ensures compliance with EU regulations for safety and legal market entry. |

| CRN | Certifies compliance with safety standards in Canada. |

| 3-A | Ensures equipment can be effectively cleaned, crucial for food and pharmaceutical industries. |

Manufacturers can take actionable steps to maintain compliance. Regular audits, staying informed about regulatory changes, and leveraging the expertise of industry leaders like Ningbo Senjun New Materials Co., Ltd. are vital. Their commitment to producing high-quality copper fin heat exchangers demonstrates how compliance can drive innovation and reliability in medical applications.

FAQ

What are medical-grade heat exchangers used for?

Medical-grade heat exchangers regulate temperature in critical medical devices like ultra-low temperature refrigerators and dehumidifiers. They ensure optimal performance and safety in healthcare environments, supporting applications such as medical refrigeration, sterilization, and bioprocessing.

Why is compliance with international standards important?

Compliance ensures safety, reliability, and regulatory approval. Standards like ISO 13485 and ASME BPE help manufacturers produce high-quality equipment, such as the Copper Fin Heat Exchanger, that meets stringent medical requirements and minimizes risks in healthcare applications.

How does the Copper Fin Heat Exchanger enhance medical device performance?

The Copper Fin Heat Exchanger provides efficient thermal management, ensuring precise temperature control in medical devices. Its design supports durability and reliability, making it ideal for demanding applications like medical refrigeration and ultra-low temperature systems.

What role does risk management play in heat exchanger production?

Risk management identifies and mitigates potential hazards during production. Standards like ISO 14971 guide manufacturers in implementing controls to prevent contamination, system failures, and other risks, ensuring the safety and reliability of medical-grade heat exchangers.

How do manufacturers ensure the sterility of heat exchangers?

Manufacturers follow ASME BPE standards, which emphasize hygienic design and material selection. They use biocompatible materials and advanced cleaning protocols to ensure sterility, making products like the Copper Fin Heat Exchanger suitable for sensitive medical environments.