In the pursuit of optimal air quality and system efficiency, understanding the role of an "Air Dryer Filter" becomes paramount. According to a report by the Environmental Protection Agency (EPA), the quality of indoor air can be two to five times more polluted than outdoor air, significantly impacting health and productivity.

With compressed air systems accounting for approximately 10% of industrial energy use, ensuring these systems operate efficiently is crucial. Studies indicate that proper filtration can reduce energy costs by as much as 30% while also prolonging the lifespan of equipment.

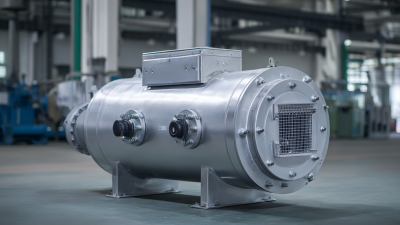

An Air Dryer Filter effectively removes moisture, particulates, and contaminants from compressed air, thereby enhancing operational efficiency and safeguarding product integrity. By incorporating advanced filtration technologies, industries can not only comply with standards but also achieve substantial savings and improved air quality.

Air dryer filters play a crucial role in maintaining the quality of compressed air systems. They work by trapping moisture and particulate contaminants that can otherwise compromise the efficiency and longevity of equipment. The filtering process begins with the air passing through a series of filtration stages, which may include coalescing filters that aggregate water droplets, allowing them to be easily removed. As the air continues through the system, finer filters capture smaller particles, including dust, oil, and other impurities. This multi-stage filtration ensures that only clean, dry air reaches the end user, preventing damage to machinery and improving operational performance.

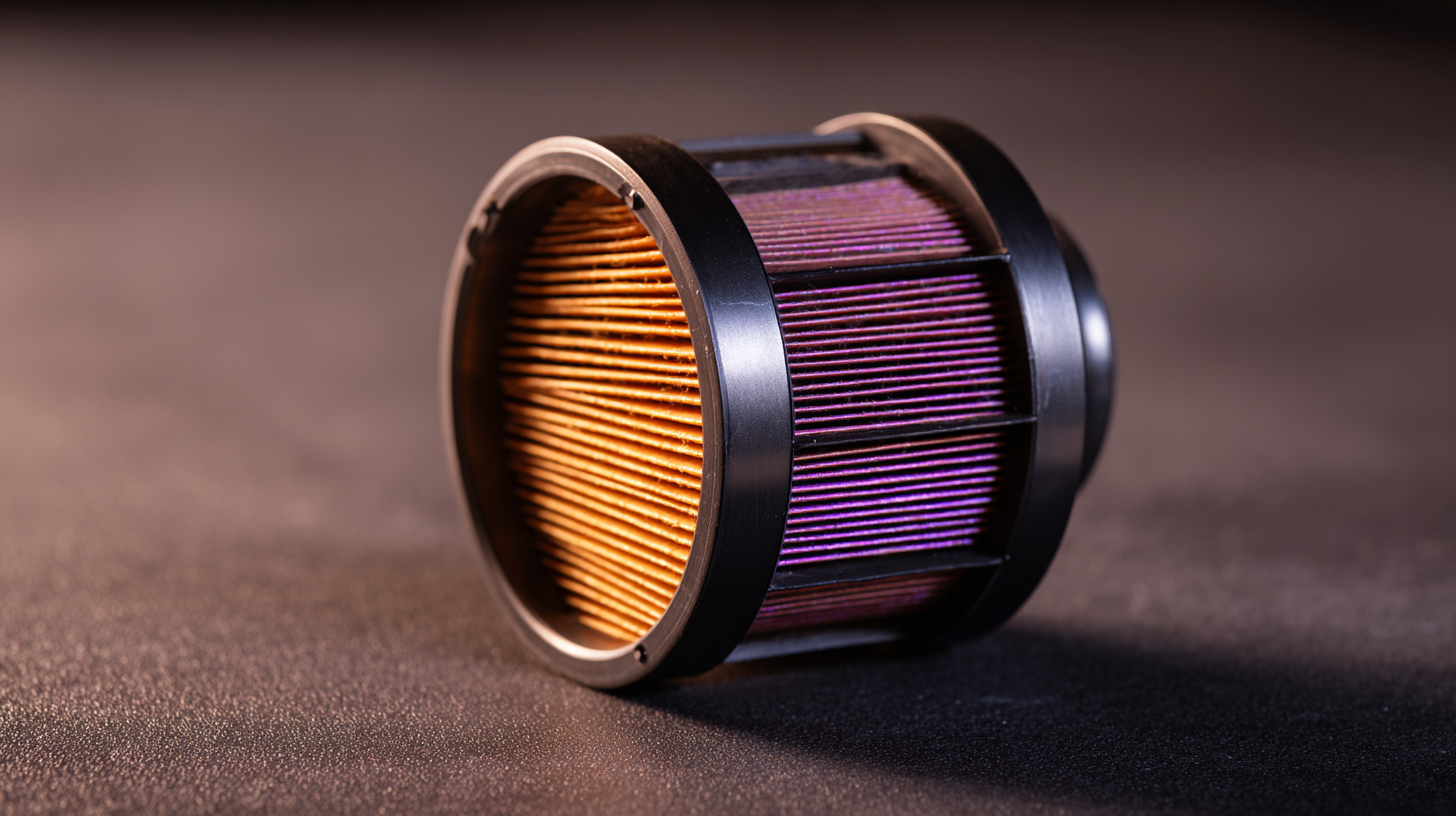

The science behind air dryer filters is rooted in principles of fluid dynamics and material science. The construction of filter media is designed to optimize the surface area for particle capture while maintaining low resistance to airflow. This balance enhances efficiency, as the system can operate at lower energy costs while ensuring maximum filtration. By employing various materials with specific pore sizes, air dryer filters can target different contaminants. Ultimately, understanding how these filters function provides insight into their significant impact on air quality and overall system reliability, making them an essential component in industrial applications.

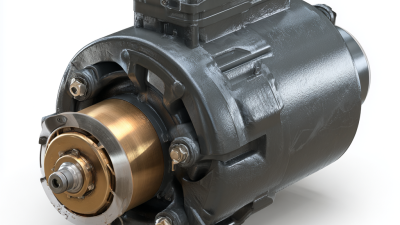

In industrial applications, maintaining air quality is crucial for both operational efficiency and the health of workers. Contaminated air can lead to equipment malfunctions and reduced performance, as particulate matter and moisture can significantly impact machinery. Additionally, poor air quality can pose serious health risks, including respiratory issues and decreased productivity among employees. Therefore, investing in effective air dryer filters becomes paramount for any industrial setting where clean air is essential.

Air dryer filters play a vital role in enhancing air quality by removing impurities from the compressed air system. These filters capture dust, oil, and water vapor, preventing them from entering equipment and production lines. By ensuring that only clean, dry air circulates, industries can improve product quality and extend the lifespan of machinery. Furthermore, with strict regulatory standards in many sectors, effective filtration systems are not just beneficial but often legally required to comply with health and safety regulations, ensuring a safe working environment for employees.

Air dryer filters play a crucial role in enhancing both air quality and system efficiency in industrial applications. According to a report by the Compressed Air and Gas Institute, nearly 75% of all industrial production facilities utilize compressed air systems, which can introduce contaminants into the air supply. By integrating high-quality air dryer filters, companies can effectively remove moisture, particulate matter, and oil aerosols, leading to a significant decrease in potential equipment damage and operational delays.

The efficiency benefits of using air dryer filters are underscored by data from the U.S. Department of Energy, which estimates that improvements in compressed air quality can lead to energy savings of up to 30%. Enhanced filtration not only prolongs the lifespan of machinery but also ensures that compressed air equipment operates at peak performance, minimizing energy usage. Furthermore, cleaner air reduces the risk of product contamination, making it essential for industries dealing with sensitive processes, such as food and pharmaceuticals, to implement robust filtration systems. By understanding and leveraging the benefits of air dryer filters, businesses can achieve a healthier work environment and more efficient operational practices.

When selecting the right air dryer filter for your system, it’s essential to consider several factors that can significantly impact performance and efficiency. First, assess the specific requirements of your application, including the type of contaminants present in the air. Different filters target various particles, such as moisture, oil, and dust, so understanding your system’s needs will help you choose the most effective option.

When selecting the right air dryer filter for your system, it’s essential to consider several factors that can significantly impact performance and efficiency. First, assess the specific requirements of your application, including the type of contaminants present in the air. Different filters target various particles, such as moisture, oil, and dust, so understanding your system’s needs will help you choose the most effective option.

Additionally, filter efficiency ratings and material construction are critical. Look for filters with high-efficiency ratings that provide adequate filtration without restricting airflow too much. Materials such as coalescing media or activated carbon can enhance performance by capturing finer particles and reducing odors. Regular maintenance and timely replacement of filters are equally important to ensure optimal air quality and prevent system damage, ultimately extending the lifespan of your air dryer system.

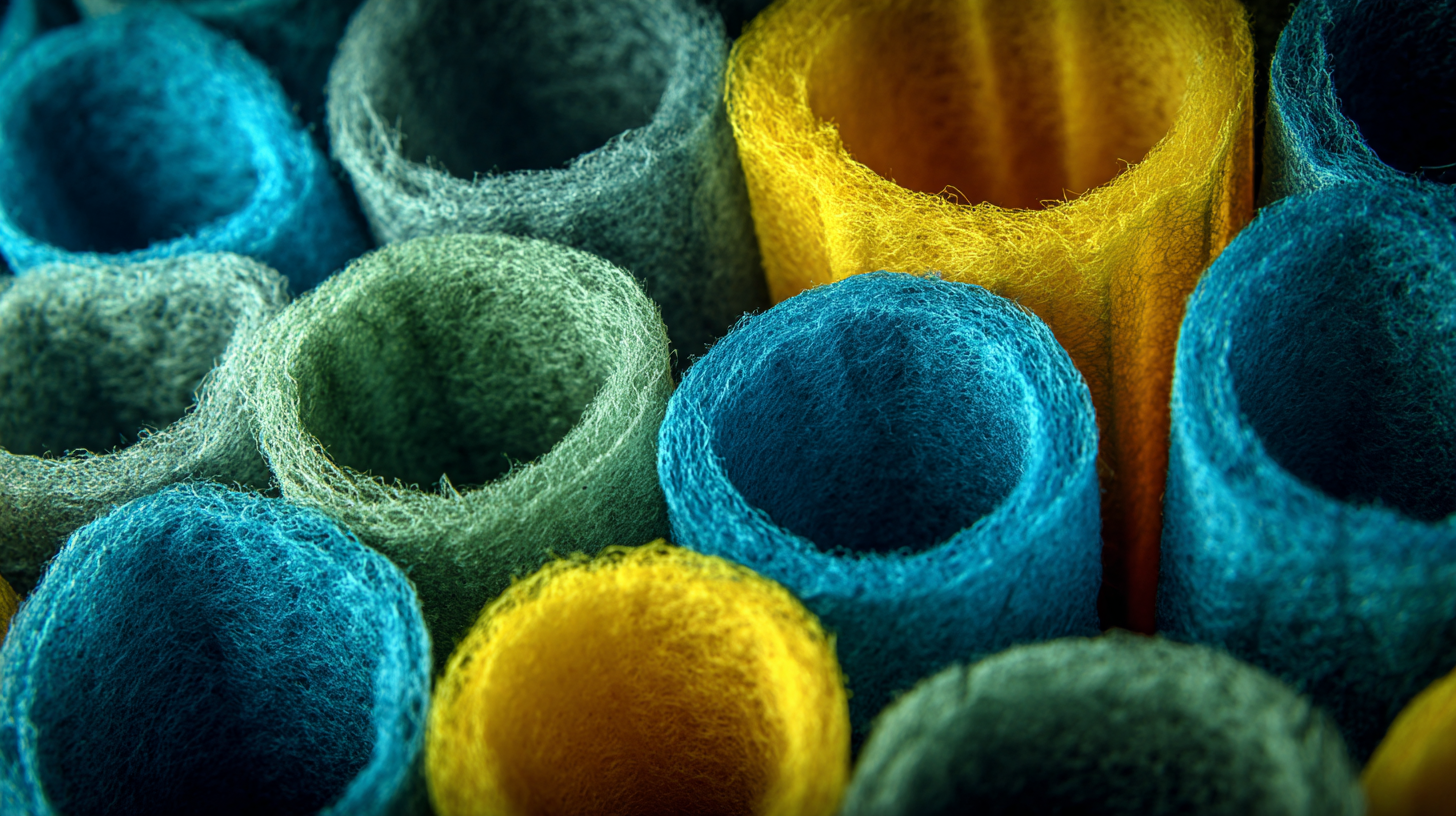

Proper maintenance of air dryer filters is essential for ensuring optimal performance and enhancing overall air quality. According to a report by the U.S. Department of Energy, regular replacement of air filters can improve energy efficiency by as much as 15%. This is largely attributed to the reduced strain on drying equipment when filters are clean and free of debris. To maximize the efficiency of air dryer filters, it’s crucial to inspect them regularly—recommended intervals are typically every 3 to 6 months.

Proper maintenance of air dryer filters is essential for ensuring optimal performance and enhancing overall air quality. According to a report by the U.S. Department of Energy, regular replacement of air filters can improve energy efficiency by as much as 15%. This is largely attributed to the reduced strain on drying equipment when filters are clean and free of debris. To maximize the efficiency of air dryer filters, it’s crucial to inspect them regularly—recommended intervals are typically every 3 to 6 months.

Additionally, keeping the filter housing clean is vital. Dust and moisture can accumulate over time, which not only impairs filter performance but also promotes microbial growth—potentially leading to air quality issues. Data from the International Journal of Environmental Research highlights that dirty filters can increase airborne particulates by up to 30%, compromising air quality. Ensuring that filters are not only replaced but also maintained properly can significantly enhance the air quality in industrial and commercial environments, contributing to both health and productivity gains.