When embarking on any project that requires airflow management, selecting the appropriate fan motor is crucial for optimal performance and efficiency. According to industry reports, such as the "Global Fan Motor Market Analysis" by MarketsandMarkets, the demand for fan motors is projected to grow significantly, driven by advancements in industrial automation and energy-efficient technologies. Fan motors are not merely components; they play a vital role in various applications, from HVAC systems to manufacturing processes, influencing both energy consumption and operational costs. Understanding the specifications, such as power rating, efficiency classes, and noise levels, is essential to ensure compatibility with your project requirements. In this guide, we will explore the key considerations and best practices for selecting the right fan motor, enabling you to make informed decisions that enhance both functionality and sustainability in your project.

When selecting a fan motor for your project, understanding your specific requirements is crucial. Begin by assessing the intended application of the fan. Are you aiming for high airflow in a cooling system, or is it more about maintaining a quiet environment in a residential area? Different applications will demand varying specifications, such as speed, torque, and noise level, which directly influence the type of motor best suited for your needs.

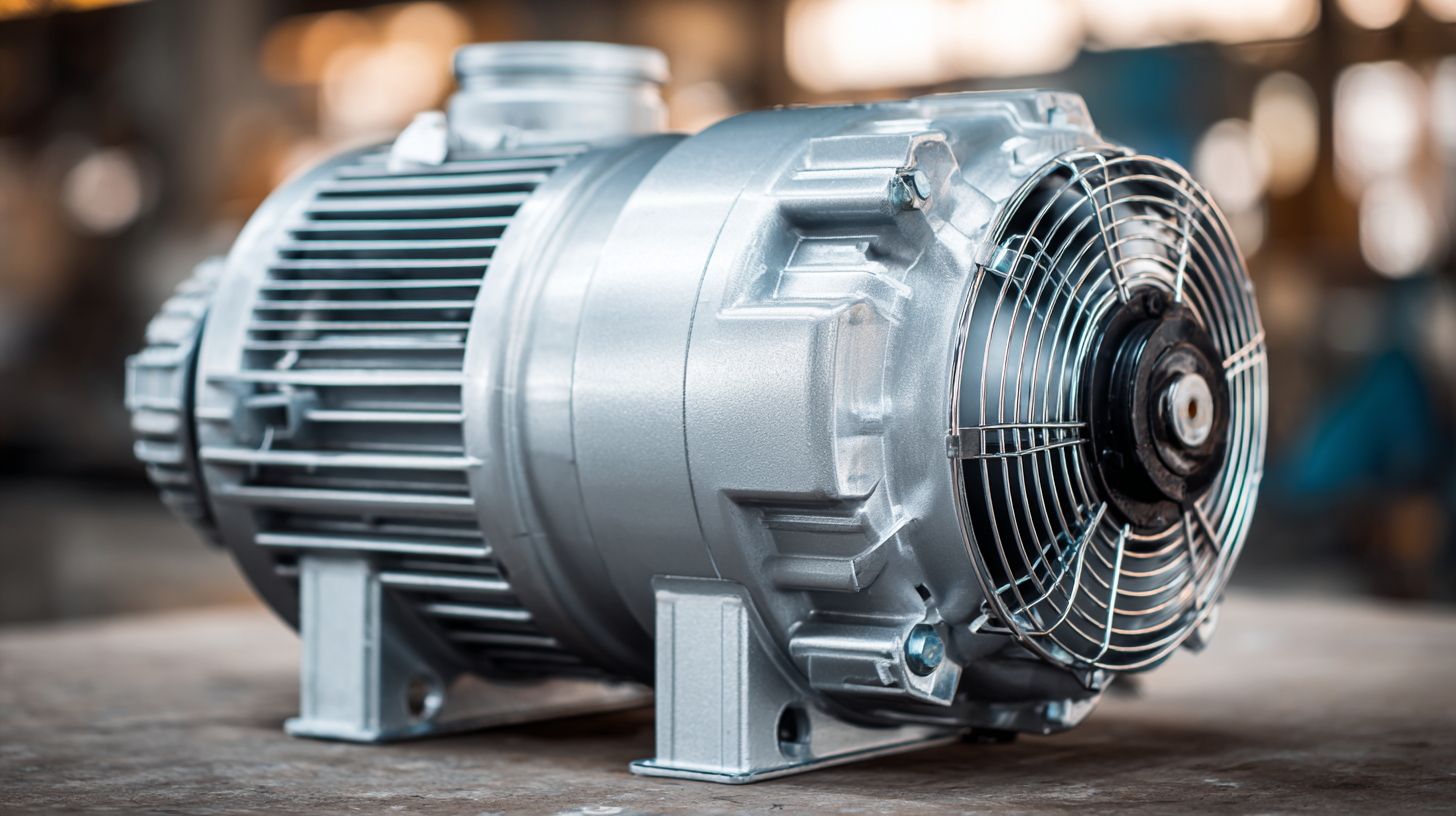

Next, consider the power supply available for your project. Fan motors can be powered by alternating current (AC) or direct current (DC), each offering distinct advantages. AC motors are typically used for larger installations requiring continuous operation, while DC motors are more efficient for variable speed and portable applications. Additionally, take into account the environmental conditions in which the motor will operate, including temperature and humidity, to ensure durability and reliability over time. By comprehensively evaluating these factors, you can select a fan motor that not only meets the technical demands of your project but also enhances overall performance.

When selecting a fan motor for your project, understanding the key specifications is crucial to ensure optimal performance and efficiency. First and foremost, consider the motor type—AC or DC. AC motors are common for larger applications due to their durability and efficiency, while DC motors are often preferred for smaller, more compact designs as they provide better speed control.

Another vital specification is the motor’s RPM (revolutions per minute). Higher RPMs can deliver greater airflow, but they may also generate more noise. Assess your project's noise requirements and balance them against the airflow needs. Additionally, pay attention to the voltage ratings; selecting a fan motor that matches your power supply is essential for safe operation.

**Tips:** Always check for the thermal rating of the motor to ensure it can handle the expected operating temperatures in your environment. Consider the size and weight of the motor as well, as this will impact the overall design and installation of your project. Finally, don't overlook the importance of warranty and support from the manufacturer; a good warranty can save you money and hassle down the road.

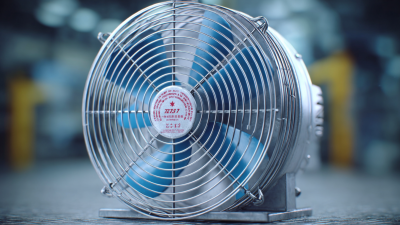

When selecting the right fan motor for your project, understanding the different types of fan motors and their applications is crucial. Electric motors are integral to a variety of sectors, from HVAC systems to automotive applications, where they are responsible for moving air, cooling systems, and even driving compressors. Recent advancements indicate that permanent magnet synchronous motors are becoming more prevalent in industrial environments due to their efficiency and effectiveness, particularly in applications including pumps and fans. This shift is indicative of the industry's growing focus on energy efficiency, as evidenced by the push for new efficiency standards set by regulatory bodies.

Tips: When choosing a fan motor, consider factors like power output and application specifics. For instance, energy-efficient motors, categorized from IE1 to IE5 based on their efficiency levels, can significantly reduce operational costs over time. Likewise, understanding the intended use—whether it's for general purpose or inverter duty-rated applications—can help tailor your selection for optimal performance.

Lastly, emerging technologies such as intelligent micro/nanomotors are gaining traction in biomedical applications, showcasing the versatility of motors beyond traditional settings. Staying informed about these innovations can provide insight into the future direction of fan motor design and their potential applications.

When selecting a fan motor for your project, evaluating energy efficiency and performance is crucial. Energy-efficient motors typically operate at higher efficiencies, which means they convert more electrical energy into useful mechanical energy. This leads to lower operating costs and reduced energy consumption over time, making them a sustainable choice for both commercial and residential applications. Look for models that meet or exceed the minimum efficiency standards set by regulatory bodies, as these motors not only save energy but often have longer lifespans.

Performance is another critical factor. The ideal fan motor should align with the specific requirements of your project, including airflow demands, noise levels, and speed control capabilities. Pay attention to the motor's specifications, such as its rated capacity (CFM - cubic feet per minute) and static pressure, as these will determine how effectively it can perform in various environments. Additionally, consider the type of motor—AC vs. DC—as DC motors tend to offer better efficiency and variable speed options, allowing for more precise control over airflow and energy use. By prioritizing both energy efficiency and performance, you can ensure that your fan motor meets your project's needs effectively while minimizing environmental impact.

When sourcing fan motors for your project, it's crucial to understand the specific requirements and constraints of your application. Begin by identifying the essential specifications such as voltage, power, size, and duty cycle. You should also consider the environment in which the motor will operate—factors like temperature, humidity, and potential exposure to dust or chemicals can significantly impact performance. Keeping these parameters in mind will help narrow down your options when comparing different models from various suppliers.

Budgeting is another vital aspect of the procurement process. While it's tempting to go for the cheapest option, be sure to account for long-term costs, including energy consumption and maintenance needs. Consider creating a cost analysis that includes not only the initial purchase price but also estimated operational costs over the motor's lifespan. Additionally, explore bulk purchasing discounts or potential partnerships with manufacturers for better pricing. By prioritizing your project's specific needs and balancing them against your budget, you can make informed decisions that will enhance the overall effectiveness and longevity of your project.

| Dimension | Value | Notes |

|---|---|---|

| Motor Type | AC, DC, Brushless | Choose based on application needs |

| Voltage | 120V, 220V, 24V | Match to your power supply |

| Power Rating | 50W, 100W, 200W | Consider airflow requirements |

| Speed Range | 1000 - 3000 RPM | Adjust based on project needs |

| Cooling Method | Air, Liquid | Select for optimal efficiency |

| Noise Level | 30 - 70 dB | Consider application environment |

| Price Range | $20 - $500 | Set according to your budget |

| Warranty | 1 year to 5 years | Longer warranty may indicate better quality |