Selecting the right Air Compressor Filter Dryer is crucial for maintaining the efficiency and longevity of your compressed air system. With a variety of options available, it can be overwhelming to determine which filter dryer best meets your specific needs. Factors such as moisture removal capacity, air flow rate, and compatibility with your existing equipment must be carefully considered. In this blog, we will guide you through the key features and considerations to evaluate when choosing an Air Compressor Filter Dryer. By understanding these elements, you can make an informed decision that ensures clean, dry air for your applications, ultimately enhancing your system's performance and reliability. Whether you're operating a small workshop or a large industrial facility, the right filter dryer can make all the difference in achieving optimal results.

Air compressor filter dryers play a crucial role in ensuring the efficiency and longevity of compressed air systems. By removing moisture, dirt, and contaminants from the compressed air, these devices protect downstream equipment from corrosion and blockages. Moist air can cause significant damage to pneumatic tools and machinery, leading to costly repairs and increased downtime. Understanding the importance of filter dryers is essential for anyone relying on compressed air for their operations.

When selecting an air compressor filter dryer, it’s vital to consider factors such as the operating pressure, flow rate, and the specific contaminants present in your air system. Different types of dryers, including refrigerated and desiccant models, cater to various industrial needs. Choosing the right filter dryer not only enhances the performance of your air compressor but also contributes to improved product quality and consistency. By investing time in understanding your requirements and selecting an appropriate filter dryer, you can ensure your compressed air system operates at its best.

When selecting an air compressor filter dryer, several key factors come into play to ensure you choose the right one for your specific needs. First and foremost, consider the type of contaminants you need to remove from your compressed air. Different filter dryers are designed to target various impurities, including moisture, oil, and particles. Understanding the source of contamination in your system is crucial for making an informed choice.

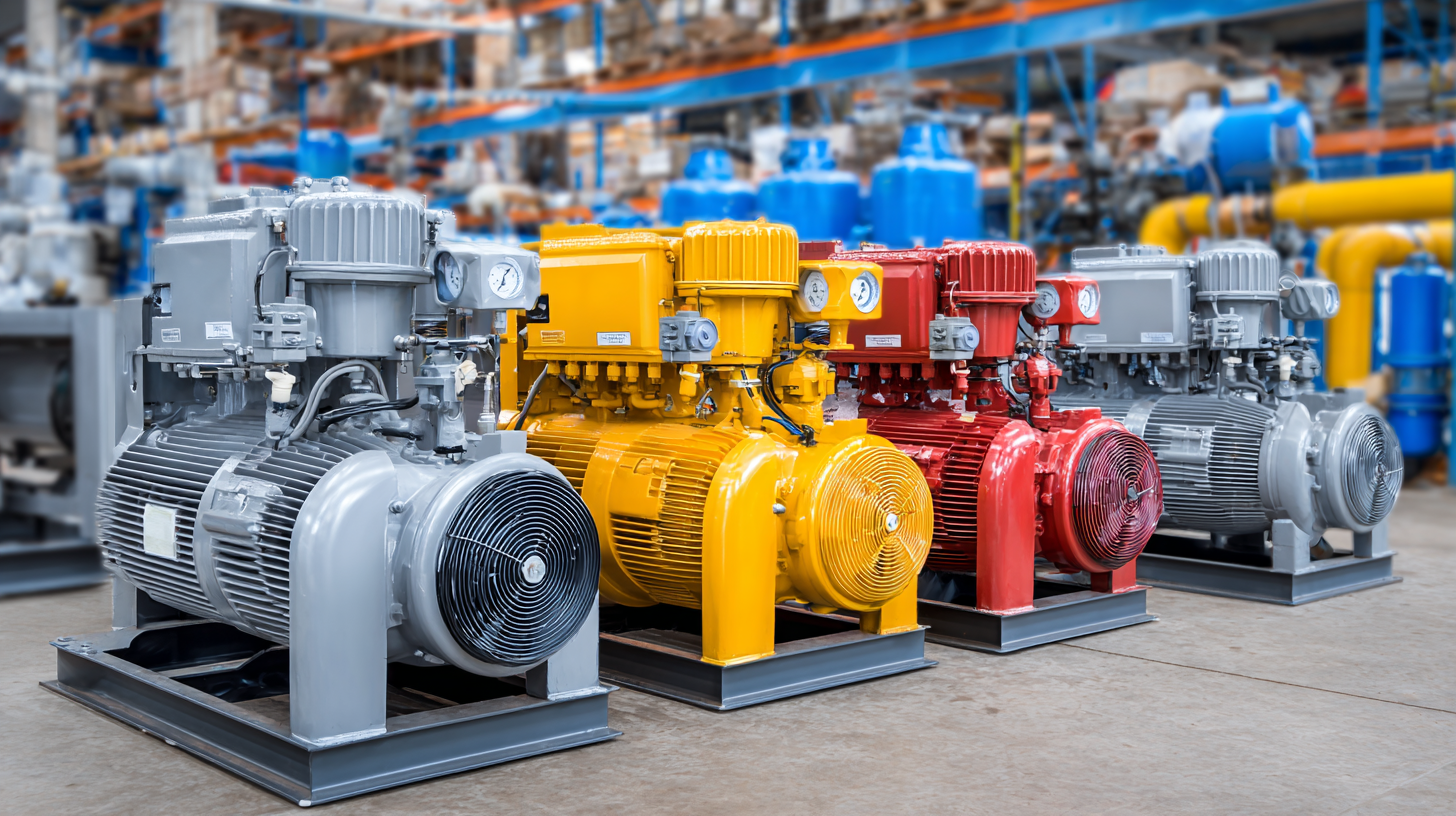

Another essential factor is the flow rate. It’s vital to select a filter dryer that can handle the maximum flow rate of your air compressor. If the filter dryer is undersized, it may lead to inadequate filtration and moisture accumulation in your system, causing damage to your equipment. Conversely, an oversized filter can lead to increased energy costs and reduced efficiency.

**Tip 1:** Always check the manufacturer's specifications to match the filter dryer capacity with your compressor's output.

**Tip 2:** Regular maintenance is key; clean or replace the filter dryer elements as recommended to ensure optimal performance and longevity.

**Tip 3:** Consider energy efficiency ratings to choose a model that not only fits your operational needs but also helps reduce long-term operational costs.

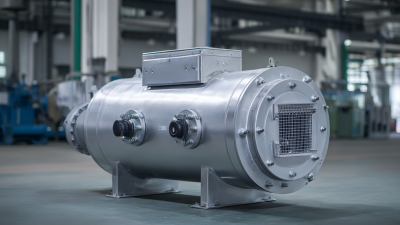

When selecting an air compressor filter dryer, understanding the types available is crucial to making an informed decision. There are three main types:

refrigerant dryers,

desiccant dryers, and

membrane dryers.

Refrigerant dryers are ideal for moderate climates and can effectively remove moisture down to 35°F, making them suitable for most industrial applications.

According to a 2022 industry report, nearly 60% of manufacturers prefer refrigerant dryers due to their balance of cost and efficiency.

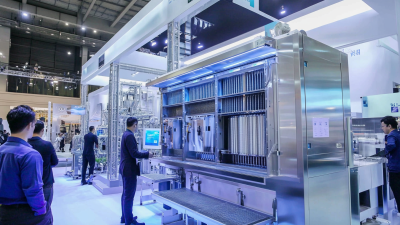

Maintaining your air compressor filter dryer is critical for ensuring optimal performance and longevity of the equipment. With advancements in drying technologies, modern air compressor systems have become increasingly efficient, contributing to cleaner production with enhanced energy efficiency and lower emissions. Research indicates that adopting energy-efficient compressed air systems can lead to operational savings of over $160,000 annually and substantial decreases in energy consumption, such as up to 2 million kWh saved per year for various facilities.

Moreover, improved dryer cartridge technologies highlight the importance of regular maintenance schedules based on the specific type and duty cycle of air compressors. As the market for compressed air treatment equipment is projected to reach USD 9.3 billion by 2024, best practices for air filter dryer upkeep will become pivotal. Companies must focus on understanding the optimal service intervals and making use of advanced monitoring systems to minimize downtime and inefficiencies, thereby enhancing production output and reducing environmental impact. Efficient maintenance practices are essential not just for performance but also for achieving corporate sustainability goals, especially in industries aiming for net-zero emissions.

When selecting an air compressor filter dryer, avoiding common pitfalls can significantly enhance your choice and system performance. A frequent mistake is underestimating the required filtration efficiency. According to industry standards, choosing a filter dryer that matches specific application needs is crucial. A study by the Compressed Air and Gas Institute (CAGI) indicates that inadequate moisture removal can lead to costly downtime and maintenance issues, stressing the need for proper moisture control in industrial applications.

Another error is not taking into account the compressor size and air flow rate. Mismatched equipment can result in poor performance and increased energy costs. It's important to select a filter dryer that can handle the volume of air generated by the compressor efficiently. Reports found that up to 70% of compressor-related failures can be attributed to improper filtration systems, underscoring the importance of aligning the filter dryer specifications with the compressor's operational parameters.

Furthermore, failing to regularly maintain the filter dryer can lead to performance degradation. Preventive maintenance, including timely replacement of filter elements, is essential in ensuring longevity and efficiency of the system. As noted in various trade publications, implementing a scheduled maintenance plan can reduce the likelihood of operational failures by up to 30%, ensuring that the air quality remains optimal for your applications.

| Dimension | Description | Common Mistakes | Recommendations |

|---|---|---|---|

| Size | Ensure it fits your installation space and airflow requirements. | Overlooking the physical dimensions. | Measure your space accurately before purchasing. |

| Type of Dryer | Select between refrigerant, desiccant, or membrane types based on needs. | Not considering the application requirements. | Evaluate the working environment for suitable dryer type. |

| Flow Rate | Ensure the dryer can handle your system's flow rate. | Choosing a dryer with inadequate flow capacity. | Check specifications against your compressor's ratings. |

| Maintenance | Consider how easy it is to maintain the unit. | Ignoring the maintenance requirements and costs. | Choose models that offer easy access for service. |

| Energy Efficiency | Evaluate energy consumption for lower operational costs. | Neglecting the impact of energy consumption. | Look for energy-efficient models with good ratings. |