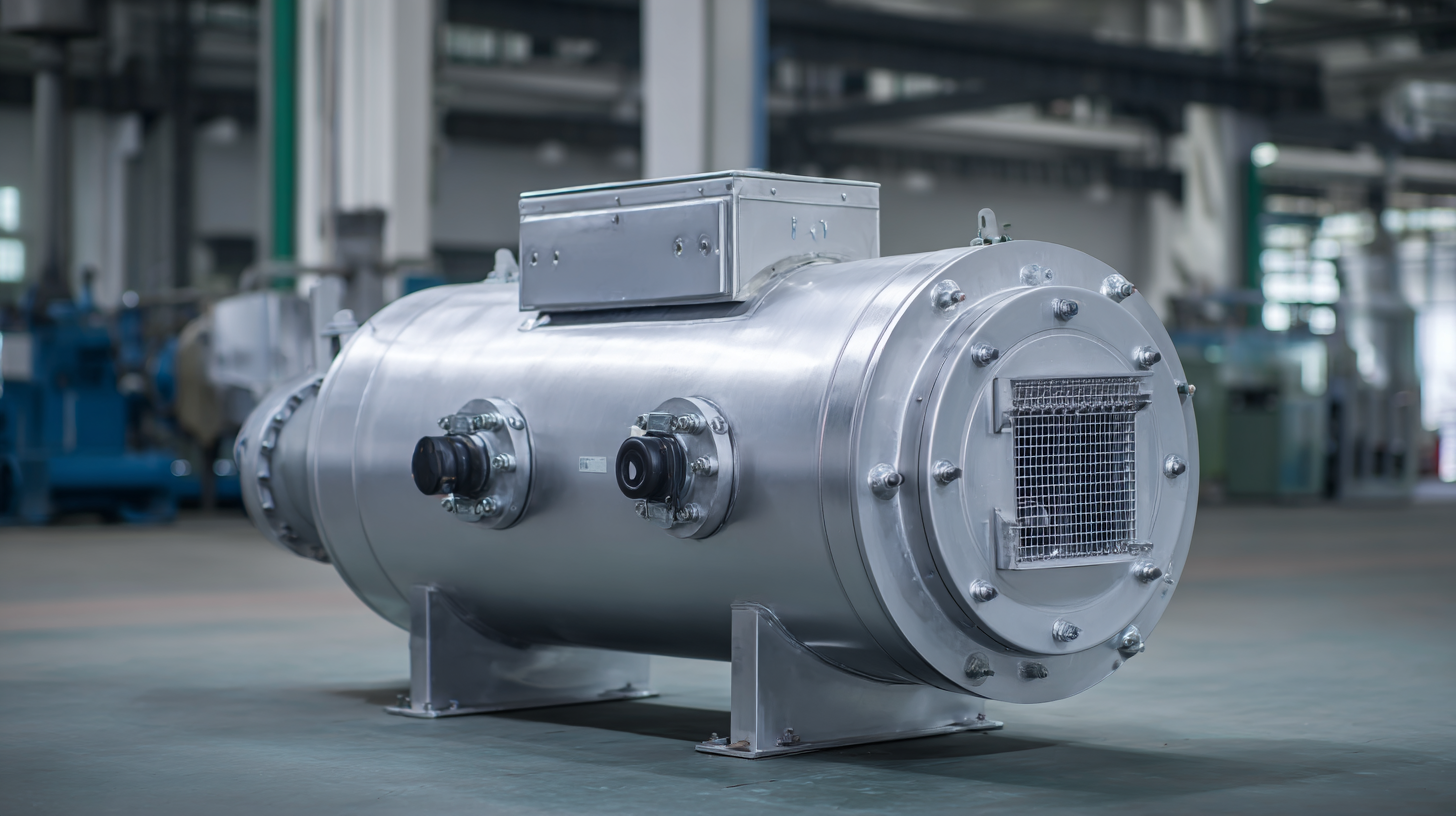

In the fast-paced industrial environment, the efficiency of compressed air systems is critical for maintaining optimal performance and productivity. Inline air dryers play a vital role in removing moisture and contaminants from compressed air, which, according to the Compressed Air and Gas Institute, can save manufacturers up to 30% in energy costs while significantly extending the lifespan of machinery. With the increasing emphasis on energy efficiency and sustainability, industries are prioritizing the use of advanced inline air dryers as part of their operational strategies. Reports from the International Energy Agency indicate that the global market for air treatment equipment is projected to grow significantly, highlighting the importance of choosing the best inline air dryers tailored for specific factory needs. In this blog, we will explore the seven best inline air dryers available, ensuring your facility operates at peak performance while minimizing downtime and maintenance costs.

Inline air dryers play a crucial role in optimizing factory efficiency by maintaining the quality of compressed air. According to a report by the Compressed Air and Gas Institute (CAGI), nearly 70% of production facilities suffer from air quality issues, which can lead to increased energy costs and equipment downtime. Utilizing inline air dryers helps to eliminate moisture from compressed air systems, thereby reducing the risk of corrosion and extending the lifespan of equipment. For instance, businesses that implement these systems can see a reduction in energy consumption by up to 30%, ultimately contributing to lower operational costs.

Moreover, inline air dryers enhance product quality by ensuring that the air used in pneumatic processes is free from contaminants. A study by the International Society of Automation (ISA) found that air quality issues could lead to defects in up to 50% of manufactured products in some industries. By effectively removing water vapor and particulates, inline air dryers can significantly reduce the incidence of product defects, ensuring higher standards of quality and bolstering customer satisfaction. Investing in such technology not only promotes efficient production processes but also drives long-term benefits for factories striving for excellence in their operations.

When selecting the best inline air dryers for optimizing performance in your factory, several key features are essential to consider.

First, look for dryers that offer efficient moisture removal capabilities.

This is crucial as excess moisture in compressed air systems can lead to product defects and increased downtime.

The ability to remove moisture effectively not only extends the life of air tools and equipment but also enhances overall productivity.

The ability to remove moisture effectively not only extends the life of air tools and equipment but also enhances overall productivity.

Another important feature to evaluate is the energy efficiency of the inline air dryer.

Models incorporating advanced technology such as variable speed drives or heat exchangers can significantly reduce energy consumption while maintaining optimal drying performance.

Additionally, consider the reliability and maintenance requirements of the unit.

A dryer designed for easy access to components and straightforward maintenance routines can minimize disruptions and ensure continuous operation, ultimately contributing to a smoother workflow in your factory.

When it comes to maximizing efficiency in a factory setting, the choice of an inline air dryer can make a significant difference. Our exploration of the top 7 inline air dryers reveals critical performance metrics that ensure optimal operation. These dryers are designed to maintain ideal moisture levels in compressed air systems, preventing damage and enhancing the longevity of tools and equipment. By evaluating their drying capacities, airflow rates, and energy efficiency, facilities can make informed decisions tailored to their specific needs.

Industry ratings further highlight the reliability and effectiveness of these inline air dryers. Models often showcase advanced features such as automatic regeneration and precise temperature control, which are essential for maintaining consistent performance. By incorporating user feedback and expert evaluations, these air dryers have earned top spots across various applications. In a competitive landscape, selecting a high-performing inline air dryer not only boosts productivity but also contributes to cost savings in maintenance and energy consumption, solidifying its value in industrial environments.

Investing in inline air dryers can significantly enhance the efficiency of operations in manufacturing environments. With moisture control being essential for the quality of products, integrating these dryers into your systems not only mitigates the risks of corrosion and damage to equipment but also ensures that production runs smoothly. The upfront costs of inline air dryers may seem substantial; however, a cost-benefit analysis reveals that the savings generated through reduced downtime and maintenance far outweigh these initial expenditures.

Moreover, inline air dryers contribute to energy efficiency, which is a crucial factor in long-term savings. By removing moisture from compressed air, these systems prevent energy loss and help maintain optimal pressure levels, leading to lower energy bills. Additionally, with a reliable air supply, manufacturers can avoid costly disruptions due to equipment failures, further underscoring the value of a well-planned investment in drying solutions. Ultimately, choosing the right inline air dryer not only drives performance but also supports a sustainable financial strategy for factory operations.

Maintaining inline air dryers is crucial for ensuring optimal performance in industrial settings. Regular inspections are essential to identify any potential issues before they escalate. Begin with checking the humidity levels and ensuring that the dryer’s temperature is effectively regulated. Keeping an eye on any signs of moisture accumulation can prevent downtime and enhance the efficiency of your operations. Additionally, replacing filters according to the manufacturer’s recommendations is vital for maintaining clean airflow and preventing contaminants from disrupting the drying process.

Another important aspect of maintenance is the lubrication of moving parts. Ensure that bearings and other mechanical components are well-oiled to extend the lifespan of the dryer and improve overall performance. It's also beneficial to implement a routine cleaning schedule to remove any dust or debris that may clog the system. Regularly updating and documenting maintenance activities allows for better tracking of performance and helps in planning future servicing, ultimately leading to a more productive and reliable drying system in your factory.