In the world of compressed air systems, the importance of selecting the right Air Dryer Filter cannot be overstated. These filters play a crucial role in ensuring the efficiency and longevity of equipment by removing moisture and particulate contaminants from compressed air. As industry expert John Smith, a leading authority in pneumatic systems, aptly puts it, "Choosing the correct Air Dryer Filter can significantly reduce maintenance costs and extend the life of your machinery."

When embarking on the journey to find the right Air Dryer Filter, it is essential to comprehend the various types available and their specific applications. Each filter serves a unique purpose, catering to different environmental and operational needs. This guide aims to provide an in-depth examination of the factors to consider when selecting an Air Dryer Filter, empowering you to make an informed decision that aligns with your operational requirements.

By understanding the nuances of Air Dryer Filters, not only can you enhance the performance of your air systems, but also contribute to a more reliable and productive work environment. Join us as we explore the critical aspects of Air Dryer Filters and equip you with the knowledge to fulfill your needs effectively.

Air dryer filters play a crucial role in maintaining the quality and performance of compressed air systems. They are designed to remove moisture, dirt, and contaminants from the compressed air, ensuring that the air delivered to tools and machinery is clean and dry. These filters operate by trapping particles and moisture as the air passes through, which helps prevent issues such as corrosion, malfunctioning equipment, and reduced efficiency. Understanding their function is vital for anyone relying on compressed air for industrial applications or DIY projects.

The importance of selecting the right air dryer filter cannot be overstated. Different applications may require different types of filters, such as coalescing filters for removing oil droplets or particulate filters for capturing solid particles. Factors like flow rate, pressure drop, and the specific contaminants present in your system should guide the selection process. By choosing the appropriate filter, users can prolong the lifespan of their equipment, reduce maintenance costs, and ensure a reliable supply of quality compressed air. This knowledge is essential for making informed decisions that enhance overall operational efficiency.

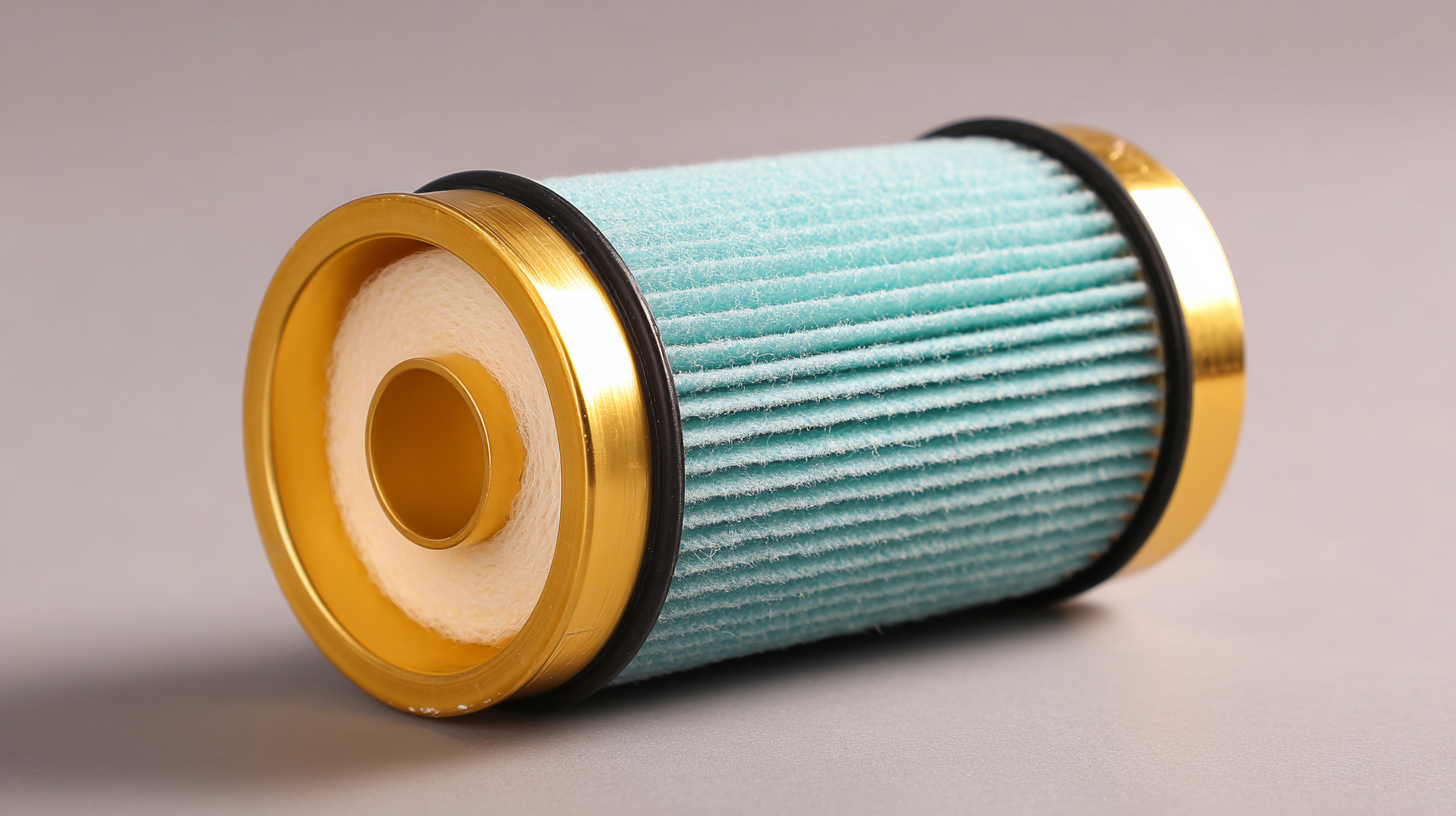

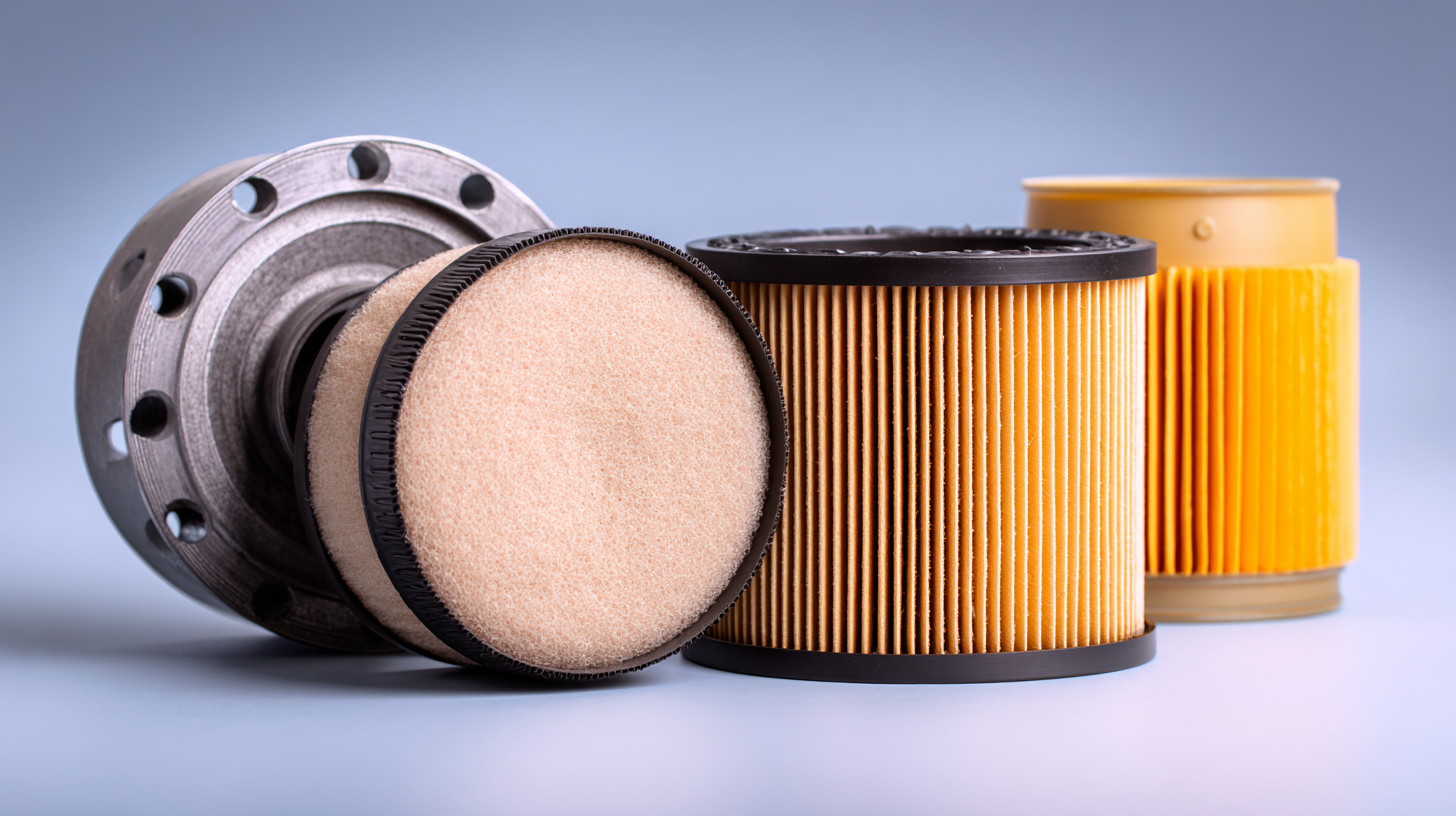

When selecting an air dryer filter, it’s essential to understand the different types available and their applications. The most common types include coalescing filters, particulate filters, and desiccant filters, each designed to tackle specific contaminants.

Coalescing filters are excellent for capturing water droplets and liquid oil from compressed air, ensuring a clean air supply that protects downstream equipment. They are particularly effective in environments where moisture levels are high.

Coalescing filters are excellent for capturing water droplets and liquid oil from compressed air, ensuring a clean air supply that protects downstream equipment. They are particularly effective in environments where moisture levels are high.

Particulate filters, on the other hand, are ideal for removing solid particles such as dust and dirt from the air stream. These filters are pivotal in industries that require a high level of cleanliness, like pharmaceuticals and food processing. Desiccant filters absorb moisture, making them suitable for applications in cold storage or areas where air quality must be meticulously controlled. Understanding the requirements of your specific application will guide you in choosing the right air dryer filter to maintain optimal performance and prolong equipment life.

When selecting an air dryer filter, there are several key factors that one must consider to ensure optimal performance and efficiency. First, it’s essential to assess the flow rate required for your specific application. According to a 2022 report by the International Air Compressor Association, filtration systems that match the flow requirements can improve efficiency by up to 15%. This means selecting a filter that can handle your system's maximum flow without causing pressure drops, which can lead to operational issues.

Another critical aspect is the filtration media type. There are various materials available, including activated carbon and coalescing filters, each designed for different applications. A recent study from the Compressed Air & Gas Institute highlighted that coalescing filters could remove particulate down to 0.01 micron, making them ideal for applications requiring high purity. Additionally, the maintenance needs and cost of replacement filters should also be considered, as these factors can significantly influence the long-term operational costs of your air dryer system.

When choosing an air dryer filter, understanding the various features and benefits available in the market can significantly enhance your decision-making process. Air dryer filters are crucial for maintaining the quality of compressed air systems, preventing contaminants such as moisture, dust, and oil from compromising performance. The best filters not only ensure cleaner air but also improve the efficiency of your equipment and prolong its lifespan.

Among the top 10 air dryer filters available, features such as filtration efficiency, pressure drop, ease of maintenance, and build quality play a vital role. For instance, filters with higher filtration efficiency can capture smaller particulates and moisture, thus providing better protection for your machinery. Additionally, ease of maintenance is important; filters designed for quick replacements can save time and resources during operation. Some filters also come with built-in pressure gauges, helping you monitor performance in real-time. Selecting the right air dryer filter involves considering these features and matching them to your specific needs to achieve optimal results in your compressed air applications.

| Filter Type | Max Air Flow (CFM) | Filtration Efficiency | Pressure Drop (PSI) | Maintenance Interval (Months) | Price Range (USD) |

|---|---|---|---|---|---|

| Coalescing Filter | 100 | 99.9% | 2 | 6 | 150 - 300 |

| Particle Filter | 80 | 99% | 1.5 | 12 | 100 - 200 |

| Activated Carbon Filter | 60 | 95% | 1 | 6 | 80 - 150 |

| Desiccant Dryer | 40 | 90% | 3 | 12 | 250 - 500 |

| Membrane Dryer | 30 | 85% | 0.5 | 24 | 300 - 700 |

Maintaining your air dryer filter is crucial for ensuring its efficiency and longevity. Regular maintenance not only extends the life of your filter but also optimizes the performance of your air dryer. One essential tip is to check and clean the filter regularly. Depending on the environment, you may need to inspect it monthly or quarterly. Dust and debris accumulation can significantly affect airflow and efficiency, so ensure you clean it according to the manufacturer's guidelines.

Maintaining your air dryer filter is crucial for ensuring its efficiency and longevity. Regular maintenance not only extends the life of your filter but also optimizes the performance of your air dryer. One essential tip is to check and clean the filter regularly. Depending on the environment, you may need to inspect it monthly or quarterly. Dust and debris accumulation can significantly affect airflow and efficiency, so ensure you clean it according to the manufacturer's guidelines.

Another important aspect is to replace the filter as needed. Set a schedule based on your usage level; for example, industrial environments may require more frequent changes compared to residential use. Additionally, always use the specifications recommended by the manufacturer to avoid compatibility issues. Keeping spare filters on hand can also reduce downtime during replacements.

Lastly, monitor the system's overall performance. If you notice a drop in air quality or increased energy consumption, it might indicate that the filter is clogged or needs attention. Addressing these issues promptly can save you time and money in the long run while ensuring that your air dryer operates at peak efficiency.